Aditya Stainless, a well-respected manufacturer and supplier based in Kolkata, India, is known for its high-performance Stainless Steel 416HT Nuts. These nuts are crafted for exceptional machinability and strength, making them perfect for applications that demand precision, durability, and resistance to moderate corrosion. With years of experience and a commitment to quality, Aditya Stainless provides Stainless Steel 416HT Nuts that adhere to international standards and meet client specifications. Catering to industries both in India and overseas, the company has built a reputation for delivering reliable products on time and at competitive prices, establishing itself as a trusted partner in the stainless steel fastening solutions market.

Stainless Steel 416HT Nuts are primarily made up of iron, chromium (12–14%), manganese, silicon, carbon, and sulfur. The “HT” signifies “High Tempered,” which means these nuts undergo heat treatment for improved strength and hardness. They boast excellent machinability, with tensile strength ranging from 760–965 MPa and a yield strength of about 550 MPa. Additionally, they have a Brinell hardness of around 262. While they may not be as corrosion-resistant as austenitic grades, they perform admirably in mildly corrosive environments and are well-suited for components that require high mechanical performance and easy fabrication.

| Grade | C | Mn | Si | P | S | Cr | Mo |

| SS 416HT | 0.15 max | 1.25 max | 1 max | 0.06 max | 0.15 min | 12 – 14 | 0.6 max |

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS 416HT | 517 | 30 | 275 | 262 | – |

Contact us to get a quick quote for your requirement.

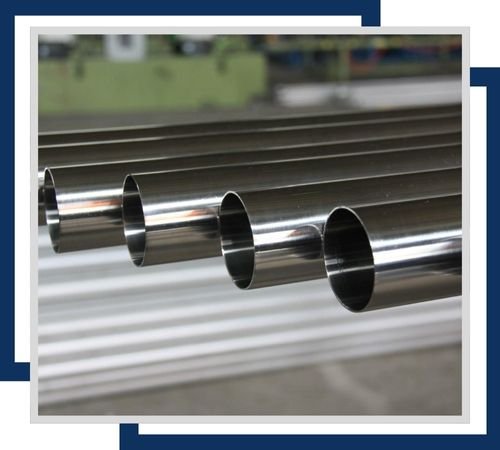

We maintains high-quality standards for Stainless Steel 416T Pipes. All the pipes undergo extensive testing such as mechanical, chemical, and dimensional checks that assure international standards compliance. We offer full certification in the form of Mill Test Certificates (MTC), EN 10204 3.1, that ensures reliability, durability, and superior performance in various industrial applications.

Stainless Steel 416HT ERW (Electric Resistance Welded) pipes are manufactured by welding stainless steel strips using an electric current, offering high strength and uniformity. Ideal for structural and fluid applications.

Stainless Steel 416HT EFW (Electric Fusion Welded) pipes are produced by fusing stainless steel plates through an electric process, providing high durability and strength. Suitable for high-pressure and high-temperature applications.

Stainless Steel 416HT LSAW (Longitudinally Submerged Arc Welded) pipes are created using a submerged arc welding process along the length of the pipe, offering high strength and resistance to harsh environments. Commonly used in large-diameter applications.

Stainless Steel 416HT Seamless pipes are manufactured without welding, providing uniform strength and resistance to high pressure and temperature. They are ideal for applications requiring high reliability and integrity.

Stainless Steel 416HT Welded pipes are produced by welding stainless steel sections, offering versatility and cost-effectiveness for various applications, including structural and industrial uses.

Stainless Steel 416HT Square pipes are precision-cut stainless steel pipes with a square cross-section, providing aesthetic appeal and structural support for architectural and construction projects.

Stainless Steel 416HT Nuts find extensive use in applications where strength, wear resistance, and machining ease are paramount. They are commonly utilized in industries such as automotive, aerospace, machinery, and precision engineering. These nuts are perfect for shafts, gears, valves, fasteners, and components that face moderate corrosive environments and mechanical stress. Their heat-treated design enhances hardness, making them ideal for high-load and high-wear applications. Thanks to their machinability, they are favored in mass-production environments where precision and cost-effectiveness are key.

©2024 Aditya Stainless All Rights Reserved.