Aditya Stainless, a prominent manufacturer and supplier located in Kolkata, India, is known for crafting top-notch Stainless Steel 439 Bars. These bars are specifically designed to offer superior corrosion resistance, thermal stability, and excellent formability. SS 439 is a titanium-stabilized ferritic stainless steel that enhances weldability and oxidation resistance compared to standard grades. Aditya Stainless provides these bars in a variety of sizes and finishes, all adhering to international quality standards for performance and reliability. They are perfect for applications in automotive exhaust systems, industrial fabrication, and architectural projects, where resistance to stress corrosion and high temperatures is crucial.

Stainless Steel 439 Bars mainly consist of 17.0–19.0% chromium, less than 0.03% carbon, under 1.0% manganese, and under 1.0% silicon, with titanium added to minimize intergranular corrosion and enhance weldability. These bars boast a tensile strength of approximately 415–450 MPa, a yield strength of at least 250 MPa, and an elongation of around 20%. The alloy excels in resisting oxidation, stress corrosion, and pitting, particularly in automotive and high-temperature settings. SS 439 also offers good formability and outstanding performance in mildly corrosive environments, making it a strong alternative to standard 409 and 430 grades.

| Standard | ASTM A276, ASTM A479 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Material Grade | Stainless Steel 439 (UNS S43035) |

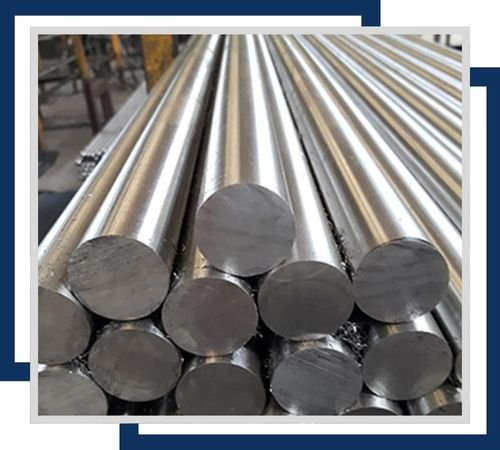

| Stainless Steel 439 Bright Bars | Outside Diameter in the range of 4mm to 500mm |

| Stainless Steel 439 Bright Bars | Outside Diameter in the range of 4mm to 100mm |

| Stainless Steel 439 Hex Bars | 18mm – 57mm (11/16″ to 2-3/4″) |

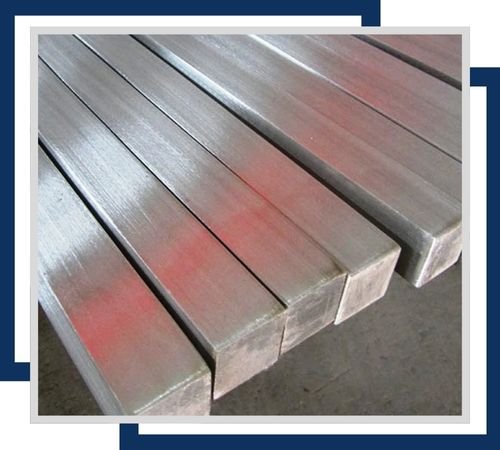

| Stainless Steel 439 Square Bars | 18mm – 47mm (11/16″ to 1-3/4″) |

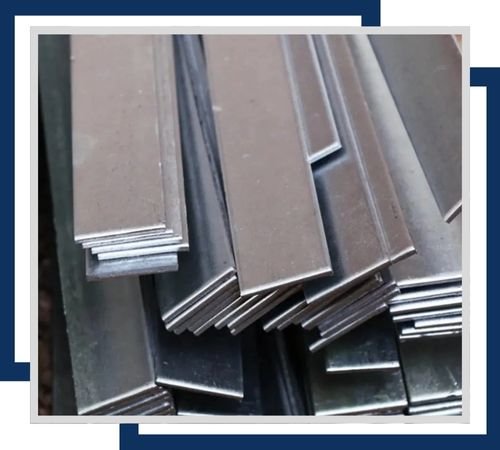

| Stainless Steel 439 Flats | 1/2” to 10” in thickness range of 2mm to 150mm, Custom Size Stainless Steel Flats available |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Grade | C | Si | Mn | P | S | Cr | Ti |

| 439 | 0.070 | 1.00 | 1.00 | 0.040 | 0.030 | 17.00~19.00 | ≥ 0.20+4(C+N)min – 0.50 max |

| Tensile strength | Yiled strength | Elongation | Hardness |

| 455 | 290 | 34 | 78 HB |

Contact us to get a quick quote for your requirement.

We ensures that all stainless steel 439 panels are rigorously tested to meet the highest standards. Each bar is mechanically, chemically and structurally analyzed. The company offers a range of relevant certifications, including Mill Test Certificates (MTC), to ensure compliance with international standards for durability, efficiency and reliability

439 round bars provide excellent corrosion resistance and high-temperature stability, ideal for automotive exhaust systems, industrial heat exchangers, and furnace components, ensuring durability in harsh environments.

439 flat bars offer good oxidation resistance and mechanical properties, suitable for applications in water heaters, heat exchangers, and structural components in construction exposed to corrosive conditions.

439 square bars are used in automotive and industrial applications, providing excellent corrosion resistance and stability, ideal for making structural components and fittings exposed to high temperatures.

439 rectangular bars deliver strong corrosion resistance and high-temperature performance, perfect for heat exchangers, furnace parts, and structural components in various industrial and construction applications.

439 hexagonal bars offer excellent resistance to oxidation and stress corrosion cracking, ideal for fasteners, fittings, and components in automotive and industrial environments requiring high durability.

439 T-bars provide good corrosion and heat resistance, suitable for structural support in construction and industrial applications, ensuring long-lasting performance in challenging environments.

Stainless Steel 439 Bars find extensive use in automotive exhaust components like manifolds, mufflers, and catalytic converter systems, thanks to their remarkable oxidation resistance and thermal stability. In the HVAC and construction industries, they are employed for air duct systems, roofing structures, and interior architectural features. These bars are also utilized in industrial fabrication, commercial kitchen equipment, and waste gas handling systems where enhanced corrosion resistance is essential. The titanium stabilization makes SS 439 particularly suitable for welding applications, ensuring durability and reliability across various demanding environments.

©2024 Aditya Stainless All Rights Reserved.