Home > Electrodes > AWS Class E309/309H-16 Electrodes

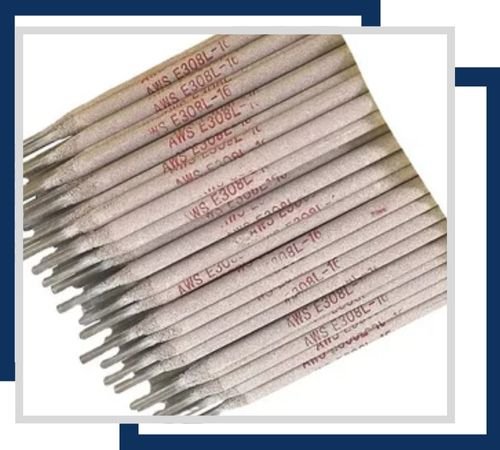

Aditya Stainless, a prominent manufacturer and supplier located in Kolkata, India, specializes in top-notch AWS Class E309/309H-16 electrodes, perfect for welding dissimilar metals and high-temperature stainless steel components. These electrodes are crafted using cutting-edge production methods and are subjected to rigorous quality checks to guarantee outstanding performance even in tough service conditions. Renowned for their remarkable arc stability, crack resistance, and oxidation resistance, Aditya Stainless’s E309/309H-16 electrodes find extensive application in fabrication, repair, and maintenance across the petrochemical, power, and refinery sectors. With dependable support and consistent product quality, Aditya Stainless has earned a reputation as a reliable provider of stainless steel welding solutions.

Aditya Stainless’s AWS Class E309/309H-16 electrodes are formulated with about 23–25% chromium and 12–14% nickel, while the “H” grade features a slightly elevated carbon content to enhance high-temperature strength. These electrodes deliver impressive tensile strength (approximately 570–620 MPa / 82,000–90,000 psi) along with good ductility. They create weld metal that exhibits strong resistance to oxidation, scaling, and thermal fatigue at high temperatures. The increased carbon level in the 309H variant boosts creep resistance while ensuring excellent weldability. These electrodes also provide smooth slag removal, stable arc characteristics, and a beautiful bead appearance in all-position welding.

| Classification | AWS A5.4, E309/309H-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E309/309H-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

Designed for welding stainless steel to mild steel or other stainless steel types, these electrodes offer high corrosion resistance. Typically available in sizes like 3/32″ to 1/8″ diameter, they provide excellent weld quality with minimal spatter.

These electrodes are ideal for general-purpose welding, offering good corrosion resistance for stainless steel applications. Sizes usually range from 1/8″ to 3/16″ in diameter, and they ensure smooth welding with light flux coatings for improved visibility and control.

Suitable for heavy-duty welding tasks, these electrodes enhance corrosion resistance and are used for thick stainless steel sections. Common sizes include 5/32″ to 1/4″ diameter, featuring a thicker coating for robust and stable arc performance.

We ensure full transparency of our AWS Class E309/309H-16 Electrodes with high-quality assurance. All orders are accompanied by all the necessary documents, such as a commercial invoice, packing list, fumigation certificate, heat treatment chart, and NABL-approved lab test report. We provide Material Test Certificate as per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third-Party Inspection Certificate. Our comprehensive documentation is organized for maximum client satisfaction.

Aditya Stainless’s AWS Class E309/309H-16 electrodes are widely utilized for welding dissimilar metals, especially stainless steel to carbon steel, and for overlaying and buffer layers in high-temperature settings. They are commonly found in industries such as chemical processing, oil and gas, power generation, and furnace fabrication. The higher carbon content in the 309H variant makes it ideal for components that face elevated temperatures and thermal cycling.

©2024 Aditya Stainless All Rights Reserved.