Home > Electrodes > AWS Class E309LMo-16 Electrodes

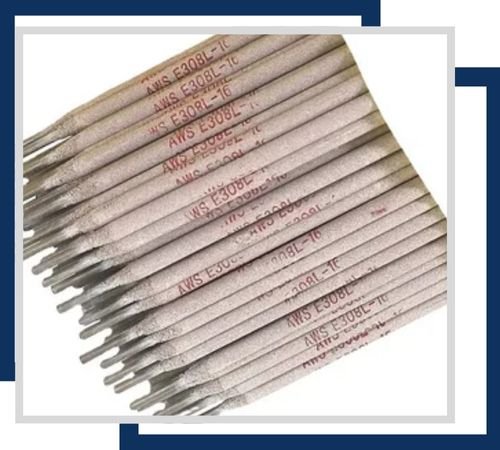

Aditya Stainless, a prominent manufacturer and supplier located in Kolkata, India, proudly offers top-notch AWS Class E309LMo-16 Welding Electrodes, celebrated for their reliability and exceptional welding performance. These electrodes are specifically crafted for welding dissimilar metals, stainless steels, and cladding applications where outstanding corrosion resistance is essential. With a strong focus on quality, precision, and customer satisfaction, Aditya Stainless guarantees that each electrode adheres to international standards and consistently performs well in challenging industrial settings. Their E309LMo-16 electrodes are extensively utilized in the chemical, petrochemical, marine, and power generation industries, solidifying Aditya Stainless’s reputation as a trusted provider of welding solutions in India and beyond.

AWS Class E309LMo-16 electrodes are composed of alloying elements such as chromium (22–25%), nickel (12–14%), molybdenum (2–3%), and a low carbon content to reduce carbide precipitation. These electrodes are engineered for superior weld metal toughness and corrosion resistance, particularly against pitting and crevice corrosion. The mechanical properties typically feature a tensile strength of around 580 MPa, a yield strength of approximately 380 MPa, and an elongation of about 30%. They provide smooth arc stability, minimal spatter, and excellent slag removal. E309LMo-16 is perfect for welding stainless steel to carbon steel and for applications exposed to harsh chemical environments.

| Classification | AWS A5.4, E309/309L-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E309/309L-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent resistance to oxidation and corrosion. They are available in 2.5 mm, 3.2 mm, and 4.0 mm diameters, designed for light-duty applications requiring minimal coating thickness.

These electrodes are known for superior corrosion resistance and are suitable for more demanding conditions. Sizes include 3.2 mm, 4.0 mm, and 5.0 mm, with a thicker coating that enhances durability and performance under heavy-duty usage.

These electrodes provide high resistance to corrosion and oxidation, featuring shielding to protect the weld from atmospheric contamination. Available in 2.5 mm, 3.2 mm, and 4.0 mm diameters, they are ideal for stable arc welding and consistent weld quality.

Our AWS Class E309LMo-16 electrodes are carefully packed in wooden boxes with waterproof protection and lifting points for ease of transport. To ensure full client satisfaction, each order is accompanied by crucial documents such as a commercial invoice, packing list, heat treatment chart and Material Test Certificates, providing full transparency and assurance of product quality.

AWS Class E309LMo-16 Welding Electrodes find extensive use in industries that require strong, corrosion-resistant welds between dissimilar metals. This includes sectors like chemical processing, petrochemical, shipbuilding, and offshore industries. They are particularly effective for joining stainless steel to mild or carbon steels and for cladding applications that need enhanced corrosion resistance due to the added molybdenum. Common applications include heat exchangers, pressure vessels, and various components in aggressive chemical environments.

©2024 Aditya Stainless All Rights Reserved.