Home > Electrodes > AWS Class E310-16 Electrodes

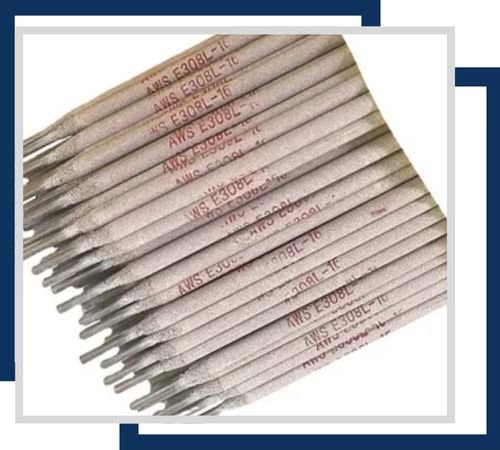

Aditya Stainless, a reputable manufacturer and supplier based in Kolkata, India, specializes in high-quality AWS Class E310-16 Welding Electrodes tailored for high-temperature applications. These electrodes are perfect for welding austenitic stainless steels found in furnace parts, heat treatment equipment, and various other high-temperature industrial components. With outstanding oxidation and scaling resistance at elevated temperatures, E310-16 electrodes are a dependable choice for demanding thermal environments. Supported by rigorous quality control and a dedication to customer satisfaction, Aditya Stainless delivers top-notch welding solutions to industries like petrochemical, power generation, metallurgy, and fabrication, both in India and abroad.

AWS Class E310-16 Electrodes are high-alloy electrodes that contain around 25–28% chromium and 20–22% nickel, providing remarkable oxidation resistance and structural stability at temperatures reaching up to 1100°C. The weld metal is entirely austenitic, offering a tensile strength of 550–700 MPa and an elongation of about 30%. These electrodes create a smooth, stable arc with minimal spatter and easy slag removal. E310-16 welds maintain their toughness and ductility even under high heat, making them perfect for applications that experience severe thermal cycling. They also resist oxidation, carburization, and scaling in extreme heat conditions.

| Classification | AWS A5.4, E310-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E310-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.08-0.20 | 25.0-28.0 | 20.0-22.5 | 0.75 | 1.0-2.5 | 0.75 | 0.03 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer exceptional corrosion resistance and are suitable for welding high-temperature alloys and stainless steels. They are available in sizes like 1/8″ and 5/32″ diameters, providing a balance of strength and ease of use.

With enhanced corrosion resistance, these electrodes are ideal for demanding welding applications involving high chromium stainless steels. They typically come in diameters of 3/16″ and 5/32″, offering robust performance and better deposition rates for thicker materials.

Known for their excellent corrosion resistance, these electrodes are designed for shielded arc welding of stainless steel and high-temperature alloys. Sizes include 1/8″ and 5/32″ diameters, providing strong welds and durability in harsh environments.

We provide full transparency of our AWS Class E310-16 Electrodes with high-quality assurance. We send all the orders with important documents, including a commercial invoice, packing list, fumigation certificate, heat treatment chart, and NABL-approved lab test report. We also offer Material Test Certificate according to EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third-Party Inspection Certificate. Our well-planned documents help us meet maximum client satisfaction.

AWS Class E310-16 Welding Electrodes are mainly utilized in high-temperature service environments due to their exceptional resistance to oxidation and scaling. Typical applications include furnace components, heat treatment baskets, kiln linings, burner tubes, heat exchangers, and thermal process equipment. These electrodes are ideal for welding stainless steels of similar composition and for joining dissimilar metals that are subjected to high heat. E310-16 is also extensively used in petrochemical plants, refineries, and steel mills.

©2024 Aditya Stainless All Rights Reserved.