Home > Electrodes > AWS Class E320LR-16 Electrodes

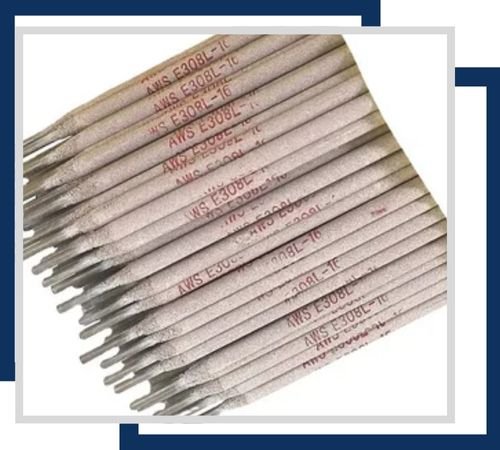

Aditya Stainless, a well-respected manufacturer and supplier located in Kolkata, India, specializes in high-quality AWS Class E320LR-16 electrodes, crafted specifically for welding high-alloy austenitic stainless steels. These low-carbon electrodes are engineered to deliver outstanding corrosion resistance and stability, even in harsh chemical and high-temperature settings. With rigorous quality control measures in place, Aditya Stainless guarantees reliable arc performance, minimal carbon absorption, and smooth weld deposits. Their E320LR-16 electrodes are perfect for critical applications that demand both strength and corrosion resistance, establishing Aditya Stainless as a trusted provider of stainless steel welding consumables for challenging industries both in India and internationally.

AWS Class E320LR-16 electrodes from Aditya Stainless feature a carefully controlled blend of chromium (~19-21%), nickel (~33-37%), molybdenum (~2-3%), and a low carbon content to avoid carbide precipitation. The “LR” (Low Residual) label signifies reduced impurities, enhancing both corrosion resistance and mechanical stability. These electrodes boast a tensile strength of around 550–620 MPa (80,000–90,000 psi) and exceptional toughness. The weld metal is resistant to stress corrosion cracking and pitting, particularly in aggressive environments like those involving sulfuric or nitric acid. They also provide a stable arc, a smooth bead appearance, and easy slag removal, ensuring high-quality welds.

| Classification | AWS A5.4, E320LR-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E320LR-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Nb + Ta | Mn | Si | P | S | Cu |

| 0.03 | 19.0-21.0 | 32.0-36.0 | 2.0-3.0 | 8 X C, min to 0.40 max | 1.50-2.50 | 0.30 | 0.02 | 0.015 | 3.0-4.0 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance and are suitable for welding stainless steel structures. They come in various diameters, such as 2.5 mm, 3.2 mm, and 4.0 mm. The light coating facilitates smooth arc stability and minimal spatter.

Providing superior corrosion resistance, heavy-coated electrodes are ideal for high-stress applications. They are available in diameters of 3.2 mm, 4.0 mm, and 5.0 mm. The heavy coating enhances the weld’s integrity and improves its resistance to oxidation.

With excellent corrosion resistance, these electrodes are designed for shielded arc welding of stainless steel. They are typically available in 2.5 mm, 3.2 mm, and 4.0 mm. The shielded arc provides enhanced protection against contamination during welding.

We ensure full transparency of our AWS Class E320LR-16 Electrodes with high-quality assurance. All orders come with essential documents, including a commercial invoice, packing list, fumigation certificate, heat treatment chart and an NABL-approved lab test report. We provide a Material Test Certificate per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report and Third-Party Inspection Certificate. Our comprehensive documentation is arranged to ensure maximum client satisfaction.

Aditya Stainless’s AWS Class E320LR-16 electrodes are specifically designed for welding alloys such as 320 and other high-alloy austenitic stainless steels, commonly used in chemical processing, pharmaceutical manufacturing, and food industry equipment. These electrodes excel in fabricating and repairing components that face strong oxidizing and reducing conditions, including heat exchangers, reactors, tanks, and piping systems. Their remarkable corrosion resistance makes them a go-to choice for demanding applications.

©2024 Aditya Stainless All Rights Reserved.