Home > Electrodes > AWS Class E330-16 Electrodes

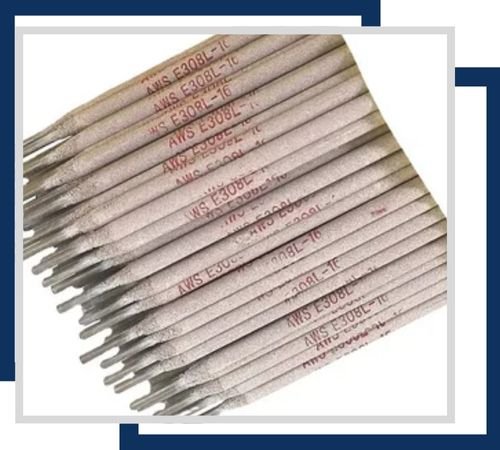

Aditya Stainless, located in Kolkata, India, stands out as a top manufacturer and supplier of premium welding consumables, with a focus on AWS Class E330-16 electrodes. Renowned for their exceptional performance and reliability, these electrodes are crafted using cutting-edge technology and rigorous quality controls to guarantee outstanding weld strength and durability. Serving a variety of industrial sectors, Aditya Stainless provides electrodes that ensure consistent results, user-friendliness, and resistance to cracking. With a strong commitment to customer satisfaction and innovation, Aditya Stainless has become a trusted name for welding solutions throughout India and beyond.

When it comes to composition and mechanical properties, Aditya Stainless’s AWS Class E330-16 electrodes boast a precisely controlled chemical makeup, typically including carbon, manganese, silicon, sulfur, and phosphorus within specific limits to achieve optimal weld quality. These electrodes offer impressive mechanical properties, featuring a tensile strength of around 480 MPa (70,000 psi) and remarkable ductility. The weld metal shows good toughness and impact resistance, making it ideal for structural steel applications. Additionally, these electrodes provide a stable arc and facilitate smooth slag removal, enhancing the appearance of the weld bead and minimizing defects.

| Classification | AWS A5.4, E330-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E330-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.18-0.25 | 14.0-17.0 | 33.0-37.0 | 0.75 | 1.0-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance for welding stainless steel. They are typically available in diameters ranging from 2.5 mm to 5.0 mm and lengths of 300 mm to 450 mm. The light coating ensures smooth arc stability and ease of operation.

Providing superior corrosion resistance, heavy-coated electrodes are designed for demanding environments. Sizes generally range from 3.2 mm to 5.0 mm in diameter and lengths of 350 mm to 450 mm. The heavy coating enhances the arc stability and weld quality in challenging applications.

These electrodes feature excellent corrosion resistance and are ideal for shielded arc welding. They come in diameters from 2.5 mm to 4.0 mm and lengths of 300 mm to 450 mm. The shielding provides effective protection against contamination during the welding process.

Aditya Stainless ensures top-quality products like AWS Class E330-16 Electrodes, verified through tests such as hardness, spectro analysis, PMI and flaring. We conduct micro and macro tests, pitting resistance, and IGC tests for guaranteed performance. Comprehensive documentation, including invoices, packaging lists and labels, is provided. Our legalized Certificate of Origin and Third-Party Inspection Certificates assure customers of our commitment to quality and customer satisfaction.

In terms of uses and applications, Aditya Stainless’s AWS Class E330-16 electrodes are extensively utilized in structural steel fabrication, construction, and heavy engineering sectors. They are perfect for welding mild and low-alloy steels in various settings, including bridges, buildings, shipyards, and machinery manufacturing. These electrodes are particularly valued for their excellent weld strength and ability to resist cracking under stress, ensuring durable joints in critical structural components. Moreover, they excel in all-position welding, making them versatile for intricate fabrication tasks. Aditya Stainless guarantees that these electrodes comply with international standards, making them a go-to choice for professionals.

©2024 Aditya Stainless All Rights Reserved.