Home > Electrodes > AWS Class E385-16 Electrodes

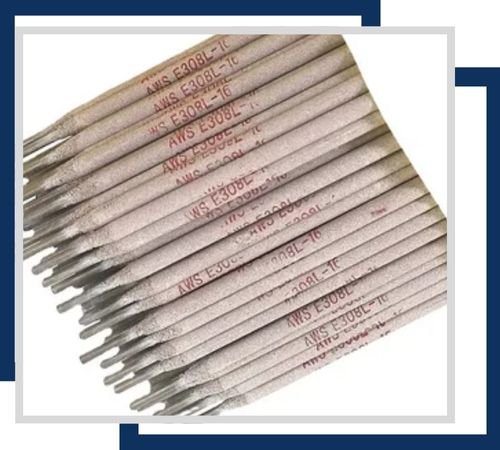

Aditya Stainless, a well-respected manufacturer and supplier based in Kolkata, India, specializes in providing high-quality AWS Class E385-16 Welding Electrodes tailored for specific welding needs. These electrodes are perfect for joining and overlaying high-alloy austenitic stainless steels like Alloy 904L. Renowned for their outstanding corrosion resistance in tough environments, Aditya Stainless’s E385-16 electrodes find extensive use in the chemical, fertilizer, and marine sectors. With a strong commitment to quality, performance, and customer satisfaction, Aditya Stainless guarantees that its E385-16 electrodes adhere to global standards, delivering dependable welding solutions for critical operations both in India and abroad.

AWS Class E385-16 Welding Electrodes are made up of significant amounts of chromium (19–21%), nickel (24–26%), molybdenum (4–5%), and copper (1–2%), making them perfect for Alloy 904L and similar steels. The weld metal boasts impressive resistance to sulfuric, phosphoric, and organic acids. Typically, the mechanical properties include a tensile strength of around 550–650 MPa, yield strength close to 350 MPa, and an elongation of about 30%. These electrodes ensure smooth arc stability, minimal spatter, and easy slag removal. E385-16 provides high-performance welds with remarkable ductility and corrosion resistance, particularly in non-oxidizing acidic and chloride-rich settings.

| Classification | AWS A5.4, E385-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E385-16 Coated Electrodes Application & uses |

|

| Grade | C | Cr | Cu | Fe | Mn | Mo | Ni | N | P | Si | S |

| SS E385-16 | 0.015 max | 20.5 max | 1.70 max | Bal | 2.10 max | 4.60 max | 25.2 max | 0.04-0.08 | 0.018 max | 0.45 max | 0.009 max |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance, particularly for welding high-strength stainless steel structures. They come in various sizes, including 3.2 mm (1/8 in) and 4.0 mm (5/32 in) diameters, providing strong welds with smooth, light coatings.

Featuring superior corrosion resistance, these electrodes are ideal for heavy-duty welding tasks. They are available in 3.2 mm (1/8 in) and 4.0 mm (5/32 in) diameters, designed for high-strength applications with thicker coatings for enhanced performance.

These electrodes are used in shielded arc welding processes for stainless steel, providing robust corrosion resistance. They are offered in sizes like 3.2 mm (1/8 in) and 4.0 mm (5/32 in) diameters, ensuring strong, reliable welds with excellent shielding properties.

We ensure full transparency of our AWS Class E385-16 Electrodes with high-quality assurance. All orders are accompanied by essential documents, including a commercial invoice, packing list, fumigation certificate, heat treatment chart, and a NABL-approved lab test report. We provide Material Test Certificates per EN 10204/3.1b, PMI Test Certificates, 100% radiography test reports, and Third-Party Inspection Certificates. Our comprehensive documentation is arranged to ensure maximum client satisfaction.

AWS Class E385-16 Electrodes are mainly utilized for welding and repairing high-alloy austenitic stainless steels like Alloy 904L. Their superior corrosion resistance makes them ideal for fabrications in the chemical, petrochemical, pulp and paper, and marine industries. These electrodes excel in environments that encounter sulfuric acid, seawater, and aggressive chlorides. Common applications include storage tanks, heat exchangers, piping systems, and chemical processing equipment. They are also used in overlay and repair work, ensuring durability and reliability in demanding conditions.

©2024 Aditya Stainless All Rights Reserved.