Home > Electrodes > AWS Class ER308/308L Mig & Tig Filler Welding Wire & Rod

Aditya Stainless stands out as a top-notch supplier and manufacturer located in Kolkata, India, specializing in high-quality welding solutions like AWS Class ER308/308L MIG and TIG Filler Welding Wire and Rod. Crafted for precision and durability, these filler materials are perfect for welding austenitic stainless steels such as 304 and 304L. Our ER308/308L wires and rods boast excellent weldability, impressive corrosion resistance, and a low carbon content that helps minimize carbide precipitation. With outstanding arc stability and clean weld deposits, Aditya Stainless guarantees reliable performance across a range of fabrication and repair tasks in industries like food processing, chemicals, petrochemicals, and architecture.

ER308/308L filler wire/rod primarily consists of 19–21% chromium and 9–11% nickel, with a maximum carbon content of 0.03% (for 308L), which helps reduce carbide precipitation during welding. Silicon (0.30–0.65%) enhances arc stability and wetting. The typical mechanical properties include a tensile strength of at least 80,000 psi (550 MPa), yield strength of at least 55,000 psi (380 MPa), and an elongation of around 30%. This filler material offers remarkable corrosion resistance in oxidizing environments and maintains toughness even at cryogenic temperatures, making it ideal for both structural and pressure-containing welds.

| Classification | AWS A5.9, ER308/308L |

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Current | MIG-DCEP / TIG-DCEN |

| Diameters | .023”, .030”, .035”, .045”, 1/16”, 3/32”, 1/8” |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ER308/308L MIG & TIG Filler Metal Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.03 | 19.5-22.0 | 9.0-11.0 | 0.75 | 1.0-2.5 | 0.30-0.65 | 0.03 | 0.03 | 0.75 |

| Yield, kpsi: | 59 |

| Tensile Strength, kpsi: | 88 |

| Elongation%, min: | 39 |

Contact us to get a quick quote for your requirement.

Alloy 308/308L MIG Filler Wire offers excellent corrosion resistance and low carbon content, making it ideal for welding 304 and 304L stainless steels in chemical, food, and beverage industries.

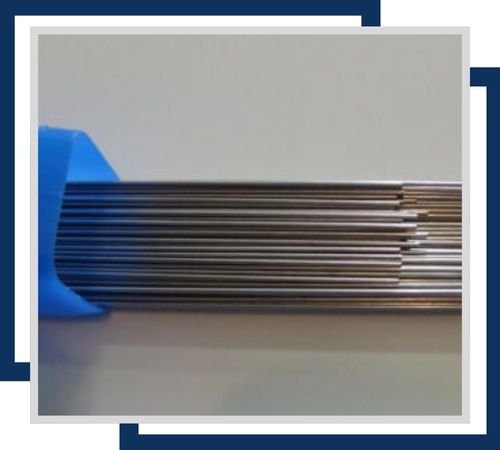

Alloy 308/308L TIG Filler Wire provides superior corrosion resistance and minimizes carbide precipitation, perfect for welding 304 and 304L stainless steels in applications requiring durability and high-quality welds.

Alloy 308/308L TIG Filler Rod is designed for welding 304 and 304L stainless steels, ensuring excellent corrosion resistance and mechanical properties, ideal for use in chemical processing and food production environments.

After manufacturing, our quality control team conducts comprehensive destructive and non-destructive tests using advanced tools to ensure the efficiency of AWS Class ER308/308L MIG and TIG Filler Welding Wire and Rod. We assure secure packaging and timely delivery to our customers. All necessary documents are provided at the time of delivery for complete transparency and satisfaction.

ER308/308L MIG and TIG filler wires and rods are extensively utilized in welding austenitic stainless steels like 301, 302, 304, 304L, and 308 grades. They are commonly found in food processing equipment, brewery tanks, dairy machinery, and chemical processing units, providing exceptional corrosion resistance and strength in sanitary and high-temperature settings. These fillers are also used in architectural structures, pharmaceutical equipment, and marine applications. The low carbon variant (308L) is particularly favored for its resistance to intergranular corrosion, especially when welding thin sections or components.

©2024 Aditya Stainless All Rights Reserved.