Home > Electrodes > AWS Class ER316/316H MIG & TIG Filler Welding Wire & Rod

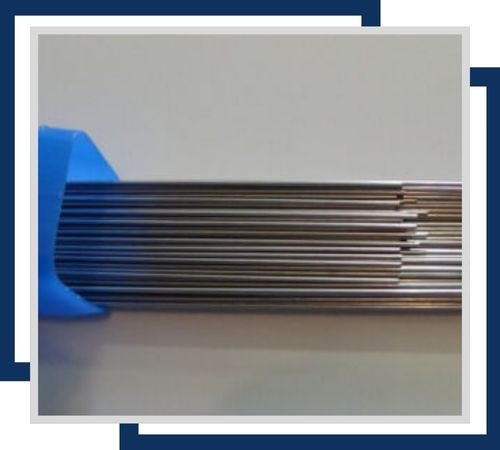

Aditya Stainless, a prominent manufacturer and supplier based in Kolkata, India, specializes in top-notch AWS Class ER316/316H MIG and TIG Filler Welding Wire and Rod. This product is specifically designed for welding molybdenum-bearing austenitic stainless steels. It’s perfect for high-temperature applications and environments that are prone to corrosion. The ER316/316H variant merges the corrosion resistance of 316 with the high-carbon properties of 316H, boosting its creep strength and performance under heat. It offers outstanding weldability, arc stability, and resistance to corrosion, particularly against chlorides and acidic solutions. This filler metal is widely utilized in industries like petrochemical, power generation, marine, and pharmaceuticals, where exceptional strength and durability are essential.

ER316/316H generally comprises 18–20% chromium, 11–14% nickel, 2–3% molybdenum, and 0.04–0.10% carbon. The addition of molybdenum significantly improves resistance to pitting and crevice corrosion, while the increased carbon content enhances strength at high temperatures and creep resistance. Its mechanical properties include a tensile strength of at least 80,000 psi (550 MPa), yield strength of at least 60,000 psi (415 MPa), and an elongation of about 30%. ER316/316H is known for its excellent weldability in both MIG and TIG processes, maintaining its mechanical and corrosion-resistant properties even in high-temperature settings, making it ideal for critical structural and pressure-retaining applications.

| Classification | AWS A5.9, ER316/316H |

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Current | MIG-DCEP / TIG-DCEN |

| Diameters | .023”, .030”, .035”, .045”, 1/16”, 3/32”, 1/8” |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ER316/316H MIG & TIG Filler Metal Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.03 | 18.0-20.0 | 11.0-14.0 | 2.0-3.0 | 1.0-2.5 | 0.30-0.65 | 0.03 | 0.03 | 0.75 |

| Yield, kpsi: | 80 |

| Tensile Strength, kpsi: | 55 |

| Elongation%, min: | 40 |

Contact us to get a quick quote for your requirement.

ER316/316H MIG filler wire provides excellent corrosion resistance and strength, ideal for welding stainless steels in chemical, petrochemical, and marine applications, with high durability in harsh environments.

ER316/316H TIG filler wire ensures superior corrosion resistance and strength for precise welding of stainless steels, suitable for high-temperature environments in industries like chemical processing and aerospace.

ER316/316H TIG filler rod offers excellent resistance to corrosion and high temperatures, ideal for welding and repairing stainless steel components in demanding applications, including chemical and marine industries.

We conduct rigorous in-house testing to ensure the highest quality and performance standards for our AWS Class ER316/316H MIG and TIG Filler Welding Wire and Rod. Our commitment to quality includes thorough inspection processes to meet industry requirements. Ensuring reliable and consistent products. With a focus on timely service, we guarantee prompt delivery, ensuring that our customers receive their orders without delay, every time.

The AWS ER316/316H MIG and TIG Filler Welding Wire and Rod are widely used for welding 316H base metals and other high-temperature austenitic stainless steels in industries that demand resistance to corrosion, heat, and mechanical stress. Common applications include pressure vessels, heat exchangers, boilers, superheaters, and process piping in chemical and petrochemical facilities. It’s also well-suited for marine environments and equipment used in pharmaceutical production. The higher carbon content ensures improved performance in these demanding applications.

©2024 Aditya Stainless All Rights Reserved.