Aditya Stainless has made a name for itself as a leading manufacturer and supplier of top-notch Stainless Steel 904L Flanges in Kolkata, India. With a reputation for precision engineering and high-quality materials, the company provides flanges that not only meet global standards but also cater to a variety of industrial needs. The SS 904L flanges from Aditya Stainless are exceptionally resistant to corrosion, pitting, and crevice attack, making them perfect for tough environments. With a strong focus on customer satisfaction, they offer tailored solutions for applications in chemical processing, marine, and oil & gas sectors. As a trusted player in Kolkata, Aditya Stainless guarantees reliable products, prompt delivery, and competitive pricing for its clients.

Stainless Steel 904L Flanges are crafted from a super austenitic alloy that includes 19–23% chromium, 23–28% nickel, 4–5% molybdenum, and 1–2% copper. This unique blend provides outstanding resistance to strong reducing acids like sulfuric acid and environments with high chloride levels. The mechanical properties boast a tensile strength of 490 MPa, yield strength of 220 MPa, and an elongation of 35%. SS 904L also retains its toughness at both cryogenic and elevated temperatures. With a hardness of 70 HRB, it ensures remarkable structural stability and longevity even in aggressive service conditions.

| Specifications | : | ASTM A/ASME SA213/ A249/ A269 |

| Dimensions | : | ASTM, ASME and API |

| SS 310/ 310S Tubes Size | : | 1/8″NB TO 30″NB IN |

| Schedule | : | SCH20, SCH30, SCH40, XS, STD, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Thickness | : | 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm. |

| Form | : | Round, Rectangular, Square, Hydraulic Etc |

| Type | : | Seamless / Fabricated / ERW / Welded / LSAW Tubes |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| AISI 904L | Maximum | Minimum |

|---|---|---|

| Ni | 28.00 | 23.00 |

| C | 0.20 | – |

| Mn | 2.00 | – |

| P | 00.045 | – |

| S | 00.035 | – |

| Si | 1.00 | – |

| Cr | 23.0 | 19.0 |

| Mo | 5.00 | 4.00 |

| N | 00.25 | 00.10 |

| CU | 2.00 | 1.00 |

| Element | Grade 904L |

|---|---|

| Density | 8 |

| Melting Range | 1300 -1390 ℃ |

| Tensile Stress | 490 |

| Yield Stress (0.2%Offset) | 220 |

| Elongation | 35% minimum |

| Hardness (Brinell) | – |

Contact us to get a quick quote for your requirement.

We practically assures its customers the top quality concerning their products, Stainless Steel 904L Tubing, with intension testing and certification measures. Each of these products is accompanied by elaborate quality checks ranging from the analysis of the material to tensile strength and corrosion resistance tests. With its international certification, the tubing guarantees excellent performance, performance reliability, and adherence to the demands of a specific industry.

Offering excellent corrosion resistance, Stainless Steel 904L Seamless Tubing is known for its uniformity and strength. It typically comes in sizes ranging from 6mm to 350mm in diameter and lengths of up to 6 meters. Ideal for applications requiring high pressure and corrosive resistance.

Stainless Steel 904L Welded Tubing provides superior resistance to chloride-induced stress corrosion cracking. Available in sizes from 10mm to 150mm in diameter and standard lengths of 6 meters. It is often used in industrial and chemical processing applications where weld strength is critical.

Featuring outstanding corrosion resistance, Stainless Steel 904L Heat Exchanger Tubes are used in demanding environments. Sizes typically range from 6mm to 50mm in diameter, with wall thickness varying from 1mm to 3mm. These tubes are designed for high temperature and pressure conditions.

Stainless Steel 904L Instrumentation Tubing offers excellent resistance to corrosion and is ideal for precise measurement systems. Common sizes include 1/8″ to 1/2″ in diameter and lengths up to 6 meters. It is suitable for high-pressure applications and harsh environments.

With superior resistance to both oxidation and corrosion, Stainless Steel 904L Boiler Tubes are used in high-pressure steam applications. Sizes typically range from 25mm to 100mm in diameter, with lengths of up to 6 meters. They are essential for maintaining efficiency in boiler systems.

Stainless Steel 904L U-tubes provide excellent resistance to corrosive fluids and are commonly used in heat exchangers. Standard sizes range from 10mm to 100mm in diameter with various lengths. They are designed to handle thermal expansion and contraction in dynamic environments.

Stainless Steel 904L Condenser Tubes are used in marine and power generation applications, offering exceptional resistance to seawater and acidic environments. Sizes typically range from 10mm to 50mm in diameter and lengths up to 6 meters, providing durability and efficiency.

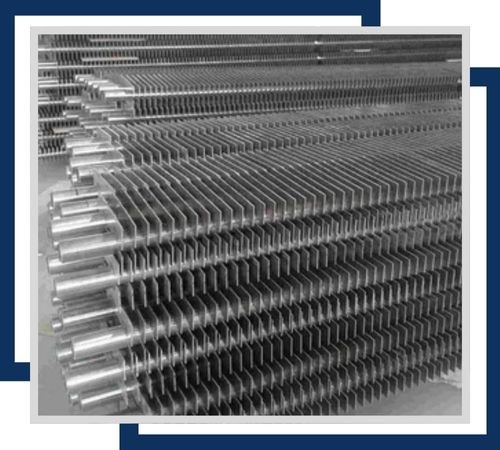

Stainless Steel 904L Fin Tubes are designed for enhanced heat transfer and corrosion resistance in air-cooled heat exchangers. They are available in various diameters, commonly 25mm to 50mm, with fin lengths customizable to specific requirements, ensuring effective cooling in challenging environments.

Aditya Stainless’s Stainless Steel 904L Flanges are widely utilized in industries that require exceptional corrosion resistance and strength. They find extensive use in chemical processing plants for managing sulfuric, phosphoric, and acetic acids. In marine settings, SS 904L flanges are favored for their ability to withstand seawater corrosion. Additionally, they are employed in oil & gas, pulp & paper, pharmaceutical, and heat exchanger applications. Throughout Kolkata and beyond, Aditya Stainless supplies SS 904L flanges for critical infrastructure where durability, low maintenance, and performance in challenging environments are crucial.

©2024 Aditya Stainless All Rights Reserved.