Aditya Stainless, a prominent manufacturer and supplier located in Kolkata, India, specializes in high-quality Stainless Steel 316 Tubing designed to cater to a variety of industrial needs. Renowned for its outstanding resistance to corrosion, especially in chloride and acidic conditions, SS 316 tubing is a go-to choice in industries such as marine engineering, chemical processing, and pharmaceuticals. Produced in line with international standards like ASTM A213, A269, and A249, these tubes come in seamless, welded, and ERW options. Aditya Stainless guarantees precise dimensions, excellent surface quality, and consistent performance, providing tubing solutions that fulfill both standard and tailored specifications.

Stainless Steel 316 Tubing consists of 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, which boosts its resistance to pitting and crevice corrosion in environments rich in chlorides. With a maximum carbon content of 0.08%, this material is highly weldable. The tubing boasts a minimum tensile strength of 515 MPa, yield strength of 205 MPa, and an elongation of 30%, with a maximum hardness of 217 HB. Its impressive thermal resistance, mechanical strength, and non-reactive surface make it perfect for transporting critical fluids in high-purity and corrosive settings.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubing

| SS | 316 |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 95 |

| Brinell (HB) max | 217 |

Contact us to get a quick quote for your requirement.

We offers high quality stainless steel 316 tubing, rigorously tested for durability, corrosion resistance and accuracy. Each tube undergoes extensive testing, including mechanical and chemical analysis, to ensure it meets industry standards. Certificates of conformity (CoC) are issued, confirming that products meet all specified requirements for performance and safety.

This tubing is available in sizes ranging from 1/8″ to 12″ in diameter and is known for its excellent corrosion resistance, particularly in marine and chemical environments. The seamless construction ensures high strength and reliability.

Typically offered in sizes from 1/4″ to 8″ in diameter, this tubing is fabricated by welding stainless steel sheets. It provides good corrosion resistance, making it suitable for structural applications and chemical processing.

Designed for heat exchange applications, this tubing generally comes in sizes from 1/2″ to 2″ in diameter. It boasts superior corrosion resistance and thermal conductivity, ideal for use in heat exchangers and condensers.

Available in sizes from 1/16″ to 1″ in diameter, this tubing is used in high-pressure and precision applications. It offers excellent resistance to corrosion and is ideal for instrumentation and process control systems.

Typically found in sizes from 1″ to 5″ in diameter, these tubes are designed for high-temperature and high-pressure environments. They provide strong corrosion resistance and durability for boiler systems.

Used in heat exchangers and other applications requiring a U-shaped tube, sizes range from 1/2″ to 4″ in diameter. They offer high resistance to corrosion and are designed for effective thermal performance.

This type comes in sizes from 1/2″ to 2″ in diameter and is used in condensers for its excellent corrosion resistance and durability in cooling applications. Ideal for heat transfer and cooling systems.

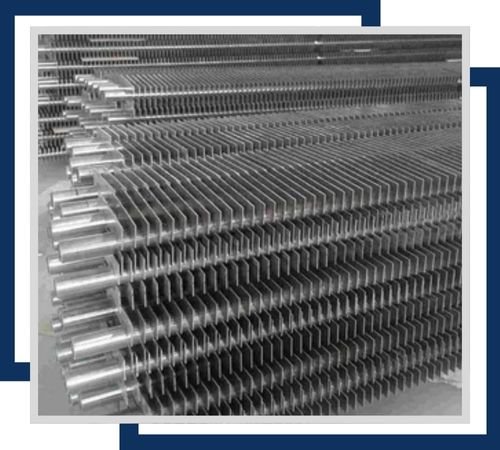

Typically available in diameters from 1/2″ to 2″, these tubes have fins attached to enhance heat transfer efficiency. They are highly resistant to corrosion and are used in heat exchangers and other cooling systems.

SS 316 Tubing finds extensive use in chemical plants, oil refineries, marine structures, and power generation facilities, thanks to its exceptional corrosion resistance and ability to withstand high pressure. It’s particularly suited for applications involving saltwater, acidic substances, and sterile conditions, making it a top choice for the pharmaceutical, biotechnology, and food processing sectors. Its hygienic features and smooth finish ensure clean fluid flow and minimize contamination risks. In heat exchangers, instrumentation lines, and hydraulic systems, 316 tubing delivers both strength and reliability.

©2024 Aditya Stainless All Rights Reserved.