Aditya Stainless stands out as a premier manufacturer and supplier of Stainless Steel 321 Bars in Kolkata, India, delivering top-notch bars designed for high-temperature and corrosive environments. SS 321 is a titanium-stabilized austenitic stainless steel known for its remarkable resistance to intergranular corrosion, oxidation, and stress rupture cracking. These bars are perfect for settings that experience frequent thermal cycling or constant exposure to high temperatures, particularly between 427–870°C. Offered in a variety of sizes, shapes, and finishes, Stainless Steel 321 Bars find applications in the aerospace, heat exchanger, chemical processing, and pharmaceutical sectors.

Stainless Steel 321 Bars consist of about 17–19% chromium, 9–12% nickel, and are stabilized with titanium (Ti) to avoid carbide precipitation. This alloy boasts a tensile strength ranging from 515–750 MPa, a yield strength of around 205 MPa, and an elongation of 30–40%. SS 321 retains its mechanical integrity even at elevated temperatures and provides superior creep and stress rupture resistance compared to 304. The titanium content boosts high-temperature performance by stabilizing the alloy against sensitization, making it an excellent choice for welding and high-temperature applications.

Standard : 321 / 1.4541

Range : 3.17mm to 350mm dia

Designation : ASTM A276, ASME SA276

Finish : Bright, Black, Polish

Thickness: 4.0mm – 100mm

Type: Bar, Bright Bar, Black Bars, Hex Bar, Square Bar, Rods, Polish Bar, Forged Bar, Round Bar

Length : Random, Fix & Cut Length

Grade | Mn | N | P | C | S | Cr | Mo | Si | Ni | Other | |

321 Stainless Steel Nuts | minimum maximum | 2.00 | 0.10 | 0.045 | – 0.08 | 0.030 | 17.0 19.0 | – | 0.75 | 9.0 12.0 | Ti=5(C+N) 0.70 |

Grade | Tensile Strength (MPa) minimum | Yield Strength 0.2% Proof (MPa) minimum | Elongation (% in 50mm) minimum | Hardness | |

Rockwell B (HR B) maximum | Brinell (HB) maximum | ||||

321 Stainless Steel Nuts | 515 | 205 | 40 | 95 | 217 |

Contact us to get a quick quote for your requirement.

At Aditya Stainless, 321 stainless steel panels are rigorously tested to ensure compliance with international quality standards. Necessary documentation, including material test reports (MTRs), chemical and mechanical analyses, and third-party testing certificates, is provided to ensure reliability, durability and accurately defined for industrial applications

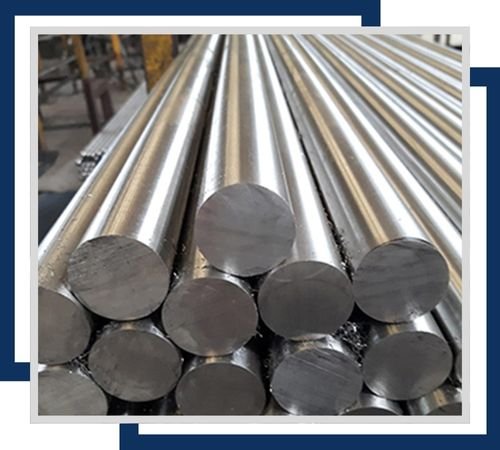

Stainless Steel 321 Round Bars Corrosion-resistant product with excellent high-temperature stability. Available in diameters from 0.5″ to 12″, ideal for aerospace and chemical processing applications where durability is critical.

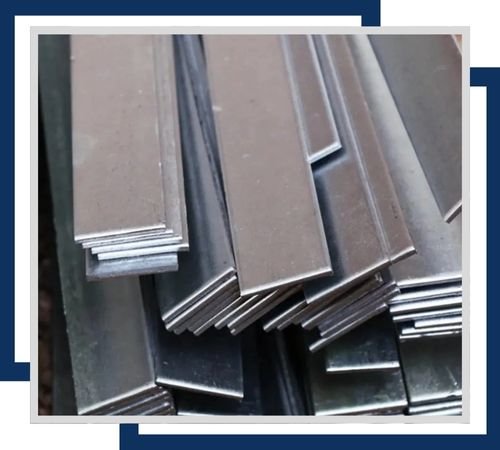

Stainless Steel 321 Flat Bars This product offers superior resistance to oxidation and is available in thicknesses from 0.25″ to 6″ and widths up to 12″. Perfect for structural and high-temperature applications.

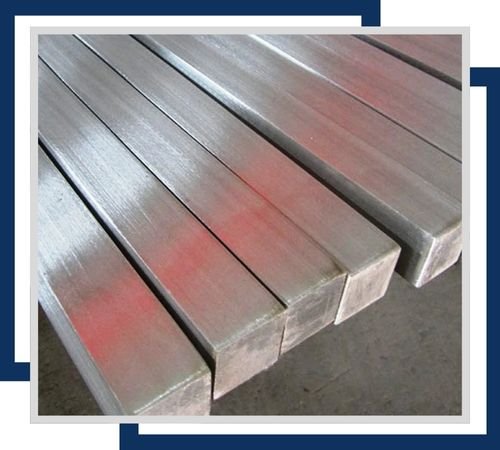

Stainless Steel 321 Square Bars Corrosion-resistant product designed for strength, available in sizes ranging from 0.5″ to 6″ on each side. Suitable for industrial applications requiring high-temperature performance.

This Corrosion-resistant product with dimensions from 0.5″ x 1″ to 6″ x 12″. Ideal for use in heavy-duty applications and structures where thermal stability is essential.

Stainless Steel 321 Hexagonal Bars Corrosion-resistant product available in sizes from 0.5″ to 4″ across flats. Used in aerospace and chemical industries where high-temperature resistance is required.

Stainless Steel 321 T-Bars Corrosion-resistant product with dimensions ranging from 0.5″ x 0.5″ to 6″ x 6″. Suitable for structural support and applications demanding high-temperature stability and strength.

Stainless Steel 321 Bars are extensively utilized in scenarios that demand high heat, corrosive conditions, and pressure. They are commonly found in exhaust manifolds, heat exchangers, furnace components, expansion joints, thermal oxidizers, and boiler parts. In the aerospace sector, SS 321 bars are essential for turbine engine components and aircraft exhaust systems. Their resistance to intergranular corrosion and outstanding performance under cyclic thermal loads make them ideal for chemical and petrochemical processing, food industry equipment, and pharmaceutical production. Their weldability and stability position them as a preferred choice in various industries.

©2024 Aditya Stainless All Rights Reserved.