Home > Sheet and Plates > Stainless Steel 410 Sheet and Plates

Aditya Stainless, a prominent manufacturer and supplier located in Kolkata, India, specializes in high-quality Stainless Steel 410 Sheets and Plates designed for strength, wear resistance, and moderate corrosion protection. As a martensitic stainless steel, SS 410 is heat-treatable and boasts impressive mechanical performance, making it a great choice for structural and engineering applications. Aditya Stainless provides these sheets and plates in a variety of thicknesses, finishes, and dimensions, all adhering to global standards. Renowned for their machinability and durability, SS 410 sheets and plates are perfect for industries such as automotive, aerospace, petrochemical, construction, and general fabrication.

Stainless Steel 410 Sheets and Plates mainly consist of 11.5–13.5% chromium, 0.08–0.15% carbon, along with small amounts of manganese, silicon, and sulfur. Being a martensitic grade, SS 410 can be hardened through heat treatment, achieving tensile strength up to 700 MPa, yield strength of at least 275 MPa, and an elongation of about 20%. This material provides moderate corrosion resistance in dry environments and good scaling resistance at temperatures reaching 650°C. Its mechanical strength and hardness make it suitable for applications that involve wear, impact, and cyclic loading.

Stainless Steel Sheets and Plates Specification : ASTM A240 / ASME SA240

Dimension Standard : JIS, AISI, ASTM, GB, DIN, EN, etc

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 120 mm

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 410 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 | 0.50 max |

| Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|

| 65 (450) | 30 (205) | 20 | 217 | 96 |

Contact us to get a quick quote for your requirement.

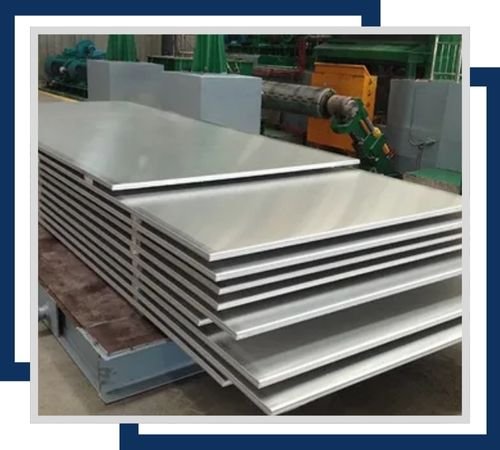

Stainless Steel 410 Hot Rolled Sheet and Plates provide high strength and durability for use in industrial machinery, automotive parts, and cutting tools. They can be used in demanding environments because of their resistance to wear and moderate corrosion.

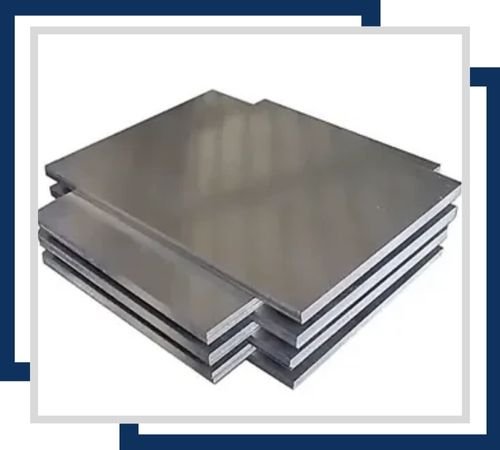

The stainless steel 410 cold-rolled sheet and plates have an excellent smooth finish along with accurate dimension, thus offering a bright outlook for their application in industries, where clean surfaces and better mechanical properties are expected, like in cutlery, surgical instruments, and various industrial components.

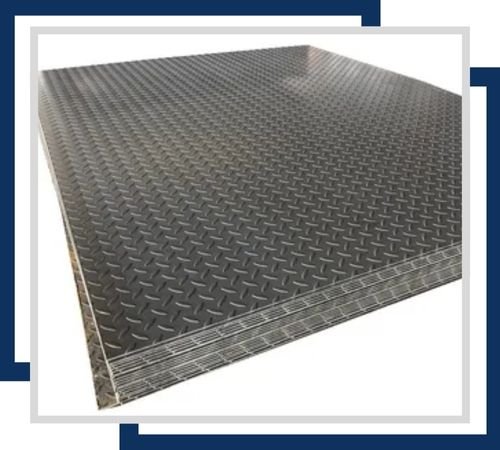

Stainless Steel 410 Chequered Sheet and Plates are slip resistant and durable and used in flooring, stair treads, and other high-traffic areas. They offer good strength and wear resistance in both industrial and commercial settings.

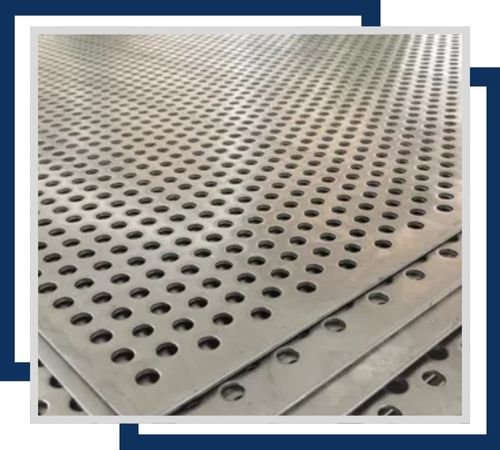

Applications like filtration, ventilation, and in custom designs call for the utilization of Stainless Steel 410 Perforated Sheet and Plates. There is strength as well as durability along with useful perforations with structural and aesthetical effects in many surrounding environments.

Stainless Steel 410 Shim Sheet and Plates are mainly applied for accuracy spacing and alignment of machinery and equipment. With respect to hardness and resistance to wear, they suit various applications which need exacting tolerance as well as resistance in industrial situations.

Stainless Steel 410 Polished Sheet and Plates come with a bright reflective finish and are ideal for decorative and architectural applications. The sheets have a good strength, and moderate corrosion resistance makes it suitable for both appearance and performance in the application environment.

Aditya Stainless is dedicated to providing an excellent customer experience, which is accompanied by detailed documentation of our high-quality Stainless Steel 410 Sheets and Plates. We provide the necessary documents, including commercial invoices, packing lists, fumigation certificates, heat treatment charts, quality assurance plans, and NABL-approved lab test reports. These documents enhance the authenticity and premium quality of our products, which builds confidence in our valued customers. In addition, different test certificates like MTC according to EN 10204/3.1b, PMI Test Certificates, 100% radiography test report, and Third Party Inspection certificates are also supplied with the Stainless Steel 410 Sheets and Plates. These certificates represent our customer-centric approach and our strong dedication to excellence in our products.

Stainless Steel 410 Sheets and Plates find extensive use in automotive parts, valve components, pump shafts, and cutlery, thanks to their strength and abrasion resistance. In the aerospace and defense sectors, they are utilized for structural brackets, housings, and fastening components. SS 410 is also well-suited for heat-resistant applications, including furnace parts, petrochemical equipment, and oil refinery components. In general engineering, these sheets and plates are employed for machinery frames, wear plates, and fabricated structural parts. Their combination of hardness, corrosion resistance, and cost-effectiveness makes them a valuable choice across various industries.

©2024 Aditya Stainless All Rights Reserved.