Home > Electrodes > Alloy 309LMo SAW and Flux

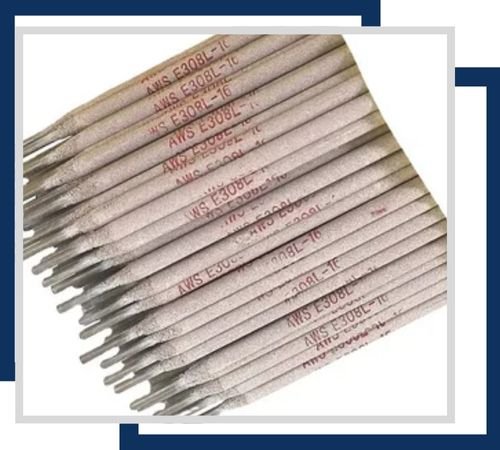

Aditya Stainless, a well-known manufacturer and supplier located in Kolkata, India, specializes in high-performance Alloy 309LMo SAW wire and flux designed for submerged arc welding. With a reputation for consistent quality and advanced metallurgical knowledge, Aditya Stainless offers welding solutions that excel in demanding applications involving stainless steel and dissimilar metal joining. Their 309LMo SAW wire and matching flux provide outstanding corrosion resistance, particularly in high-temperature and chloride-rich settings. Committed to quality control and customer satisfaction, Aditya Stainless serves industries like chemical processing, power generation, and marine fabrication by supplying reliable and efficient SAW consumables for critical welding tasks.

Alloy 309LMo SAW wire from Aditya Stainless is composed of chromium (23–25%), nickel (12–14%), molybdenum (~2.2%), and low carbon, which together provide excellent corrosion and oxidation resistance. The molybdenum content significantly boosts resistance to pitting and crevice corrosion, especially in acidic or chloride-rich conditions. When used with the right flux, it yields weld metal with a tensile strength of around 550 MPa (80,000 psi) and showcases impressive toughness and creep resistance at high temperatures. Additionally, the weld deposit maintains good ferrite control, minimizing the risk of hot cracking during the welding process.

| Classification | AWS A5.9, 309LMo |

| Form | Welding Fluxes and Wires |

| Type Of Welding | Submerged Arc Welding |

| Thickness available | Upto 4 mm |

| AWS 309LMo SAW & Flux Application & uses |

|

| C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| 0.03 max | 1.0-2.5 | 0.30-0.65 | 23-25 | 12-14 | 0.03 max | 0.03 max | 2-3 | 0.75 max |

| Tensile Strength | 89,900 |

|---|---|

| Yield Strength | 63,800 |

| Elongation (%) | 42% |

Contact us to get a quick quote for your requirement.

Alloy 309LMo SAW/Flux Welding Wire is used for submerged arc welding, providing high resistance to corrosion and oxidation, excellent weld strength, and a clean, slag-free finish for demanding applications.

Industrial 309LMo SAW Wire & Flux are used for submerged arc welding, offering high corrosion and oxidation resistance, strong welds, and a clean, slag-free finish, suitable for harsh industrial applications.

SFA A5.9 309LMo SAW & Flux are specified for submerged arc welding, providing superior corrosion and oxidation resistance, strong welds, and a clean, slag-free finish for demanding industrial environments.

We provide comprehensive documentation for our Alloy 309LMo SAW and Flux, ensuring transparency and reliability. This includes a commercial invoice, packaging list, fumigation certificate, heat treatment chart and quality assurance plan. A NABL-approved lab test report guarantees adherence to strict standards. Additionally, we offer various test certificates, including MTC as per EN 10204/3.1b, PMI, 100% radiography test and a Third-Party Inspection Certificate. These measures ensure complete client satisfaction and product integrity.

Aditya Stainless’s Alloy 309LMo SAW wire and flux are perfect for welding dissimilar metals, such as stainless steel to carbon steel, and for cladding applications that demand corrosion and heat resistance. These products are widely utilized in chemical plants, refineries, offshore structures, and marine environments where high-performance, corrosion-resistant welds are crucial. The alloy’s remarkable resistance to harsh chemicals and thermal cycling makes it an excellent choice for pressure vessels, heat exchangers, and storage tanks. Aditya Stainless is dedicated to ensuring its SAW products meet the highest standards for quality and performance.

©2024 Aditya Stainless All Rights Reserved.