Home > Electrodes > AWS Class E308/308H-16 Electrodes

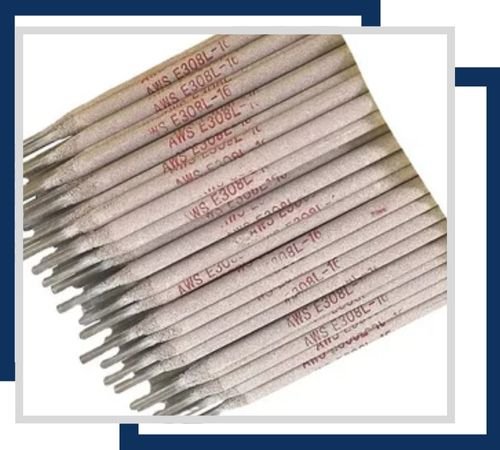

Aditya Stainless, a well-respected name in the world of welding consumables located in Kolkata, India, proudly offers top-notch AWS Class E308/308H-16 Electrodes designed for manual arc welding of austenitic stainless steels. These electrodes are expertly crafted for welding 304 and 304H stainless steels, along with similar grades. The E308/308H-16 combines the impressive corrosion resistance of ER308 with the added benefit of higher carbon content from 308H, making it perfect for high-temperature applications. With a rutile coating, these electrodes ensure stable arc performance, easy slag removal, and smooth weld beads. Aditya Stainless is committed to delivering consistent quality and performance, catering to the needs of construction, chemical processing, pressure vessels, and general fabrication industries.

E308/308H-16 electrodes are made up of about 18–21% chromium, 9–11% nickel, and a carbon content ranging from 0.04–0.08% (which is higher than standard 308 for enhanced high-temperature strength). These electrodes typically achieve a tensile strength of ≥ 80,000 psi (550 MPa), a yield strength of ≥ 55,000 psi (380 MPa), and an elongation of around 30%. The weld metal is known for its good oxidation resistance and toughness even at elevated temperatures. The “16” designation signifies that these electrodes can be used with both AC and DC current, producing a smooth, spray-like arc with minimal spatter. The higher carbon variant (308H) boosts creep resistance, making it ideal for high-heat service conditions.

| Classification | AWS A5.4, E308/308H-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E308/308H-16 Coated Electrodes Application & uses |

|

| C | Cr | Cu | Ferrite | Mn | Mo | Ni | Si |

| 0.04 % | 20 % | 0.10 % | 9 FN % | 1.80 % | 0.30 % | 10 % | 0.50 % |

Contact us to get a quick quote for your requirement.

Light-coated electrodes are ideal for welding 18-8 austenitic stainless steel, offering smooth weld beads with minimal slag formation. Available in sizes ranging from 3/32″ to 5/32″ in diameter, they are suited for applications where easy slag removal is essential.

Heavy-coated electrodes provide enhanced slag control and stable arc characteristics, making them suitable for high-heat applications. These electrodes come in sizes from 3/32″ to 5/32″ in diameter and are ideal for out-of-position welding due to their robust coating.

Shielded arc electrodes offer high weld quality with reduced spatter, making them excellent for shielded arc welding. Available in sizes ranging from 3/32″ to 5/32″ in diameter, they provide superior arc stability and slag detachability, resulting in cleaner welds.

We guarantee quality products such as AWS Class E308/308H-16 Electrodes that consistently pass all tests, such as hardness testing, spectro analysis, PMI, flaring tests, macro and micro tests, pitting resistance, and IGC tests. We ensure all documentation requirements such as commercial invoices, packaging lists, Certificate of Origin, and Third-Party Inspection Certificates to ensure the finest quality and satisfaction of our valued customers.

AWS E308/308H-16 electrodes are perfect for welding austenitic stainless steels like 304, 304H, and 308 grades in situations where corrosion resistance and high-temperature strength are essential. They find extensive use in industries such as chemical processing, petrochemical, power generation, and food processing. These electrodes are especially well-suited for applications involving boilers, heat exchangers, furnace components, and pressure vessels that operate under high temperatures. The increased carbon content significantly enhances mechanical strength in thermal service conditions.

©2024 Aditya Stainless All Rights Reserved.