Home > Electrodes > AWS Class E309/309L-16 Electrodes

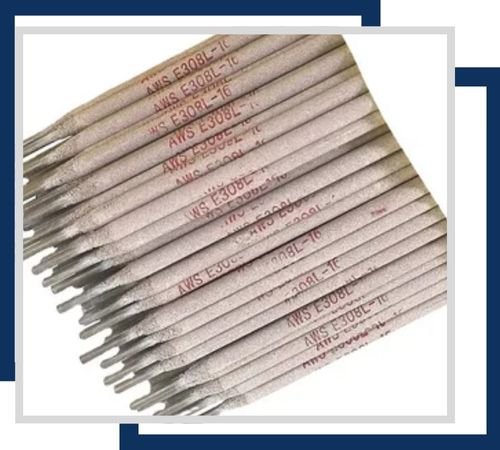

Vinit Stainless, a reputable manufacturer and supplier located in Chennai, India, specializes in high-performance AWS Class E309/309L-16 electrodes. These electrodes are specifically crafted for welding dissimilar metals and stainless steels to mild or carbon steels. They boast impressive resistance to heat, oxidation, and corrosion, even in extreme temperatures. With meticulous alloying and rigorous quality control, Vinit Stainless guarantees smooth arc stability, minimal spatter, and clean weld profiles. Commonly utilized in fabrication, maintenance, and cladding tasks, the E309/309L-16 electrodes are perfect for critical operations in petrochemical plants, refineries, power plants, and structural engineering projects that demand durable, high-integrity welds.

Vinit Stainless’s AWS Class E309/309L-16 electrodes are made up of about 23–25% chromium and 12–14% nickel, featuring a low carbon content to reduce intergranular carbide precipitation. These electrodes deliver a typical tensile strength ranging from 550–620 MPa and exceptional ductility, ensuring dependable welds in high-temperature and corrosive settings. The low-carbon variant (309L) enhances resistance to sensitization and boosts long-term corrosion performance. The weld metal is resistant to oxidation and scaling, allowing for easy slag removal, a stable arc, and a finely rippled weld bead, making them ideal for multi-pass and positional welding.

| Classification | AWS A5.4, E309/309L-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E309/309L-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer good resistance to oxidation and corrosion in moderate environments. Typically available in sizes ranging from 1/16″ to 1/8″ in diameter, they are ideal for applications requiring light coatings and smooth welding.

Designed for enhanced corrosion resistance and durability, these electrodes are available in diameters from 3/32″ to 5/32″. The heavy coating ensures a robust weld in demanding conditions, providing stronger welds with superior mechanical properties.

Offering excellent corrosion resistance, these electrodes are used in shielded metal arc welding applications. They are available in diameters such as 1/16″, 3/32″, and 1/8″, providing versatile options for various welding needs.

We take great care in securely packing and shipping our AWS Class E309/309L-16 Electrodes, using wooden boxes with waterproof material and lifting points for easy transport. Along with each order, we provide essential documents, including a commercial invoice, packing list, heat treatment chart and material testing certificates. Our comprehensive documentation ensures full transparency and guarantees client satisfaction.

The AWS Class E309/309L-16 electrodes from Vinit Stainless are perfect for welding dissimilar metals, such as connecting stainless steel to carbon or low-alloy steel, and for establishing buffer layers before overlay welding. These electrodes find extensive use in chemical processing plants, oil refineries, heat exchangers, boilers, structural frameworks, and power generation equipment. They are particularly effective in environments subject to thermal cycling and corrosive media. The low-carbon 309L variant ensures outstanding corrosion resistance, making it a reliable choice for various applications.

©2024 Aditya Stainless All Rights Reserved.