Home > Electrodes > AWS Class E316/316H-16 Electrodes

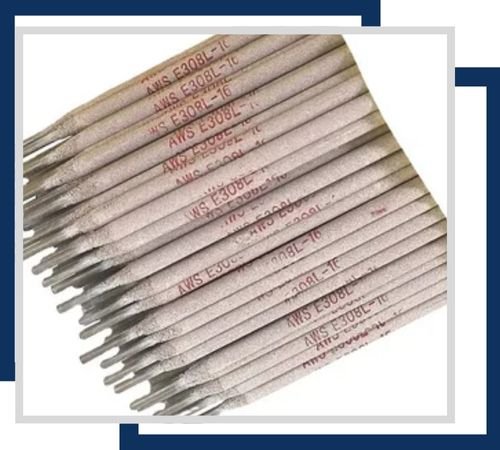

Vinit Stainless, a well-respected manufacturer and supplier located in Chennai, India, specializes in high-quality AWS Class E316/316H-16 electrodes, perfect for welding molybdenum-bearing austenitic stainless steels. These electrodes are crafted specifically for high-temperature and corrosive settings, providing exceptional weld strength and durability. Vinit Stainless guarantees that every electrode adheres to strict quality standards, ensuring consistent arc performance, minimal spatter, and outstanding corrosion resistance. Catering to industries like chemical processing, power generation, and pharmaceuticals, Vinit Stainless has established itself as a reliable name in stainless steel welding solutions, supporting intricate fabrication and critical structural projects both in India and abroad.

The AWS Class E316/316H-16 electrodes from Vinit Stainless are made with an alloy of 18–20% chromium, 11–14% nickel, and 2–3% molybdenum, with the 316H grade featuring a higher carbon content to boost high-temperature creep strength. These electrodes typically deliver a tensile strength of 550–620 MPa, along with excellent ductility and resistance to pitting and crevice corrosion, particularly in chloride-rich environments. The weld deposit remains mechanically stable under thermal stress and showcases smooth bead formation, low spatter, and easy slag removal, making them ideal for both structural and pressure-retaining stainless steel components.

| Classification | AWS A5.4, E316/316H-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E316/316H-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

Known for exceptional resistance to corrosion and high temperatures, these electrodes are ideal for welding stainless steel structures. They typically come in diameters of 1/8″, 3/16″, and 5/32″ and are designed for shielded arc welding processes, ensuring strong, durable welds.

Light-coated electrodes are suitable for welding thin sections of stainless steel and offering high corrosion and oxidation resistance. They are available in sizes such as 1/8″ and 5/32″, providing ease of use and flexibility in various welding applications.

These electrodes provide superior corrosion resistance and durability, making them ideal for heavy-duty applications. With diameters ranging from 3/16″ to 1/4″, they are designed for robust welding tasks, ensuring strong joints and long-lasting performance in harsh environments.

We ensure products of high quality such as AWS Class E316/316H-16 Electrodes with hard-testing, spectro-analysis, PMI, and flare tests. On the other hand, we ensure high quality material delivery through micro-macro tests, pitting resistance, and IGC tests. In addition to these, full documentation of commercial invoices, packaging lists, third-party inspection certificates, along with legalized certificate of origin for an unmatched satisfaction level from the customer side while being sure about product reliability.

Vinit Stainless’s AWS Class E316/316H-16 electrodes are perfect for welding 316/316H stainless steels, which are widely used in chemical plants, petrochemical refineries, pulp and paper mills, power boilers, and food processing equipment. The increased carbon content in the 316H grade makes these electrodes especially suitable for applications that face high temperatures and long-term service. They excel at resisting scaling and corrosion in harsh environments, including acidic and chloride-rich conditions, ensuring reliable performance in demanding applications.

©2024 Aditya Stainless All Rights Reserved.