Home > Electrodes > AWS Class E317L-16 Electrodes

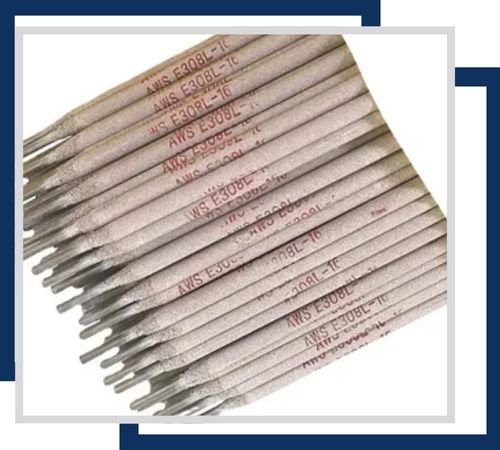

Aditya Stainless, a leading manufacturer and supplier based in Kolkata, India, specializes in high-quality AWS Class E317L-16 Welding Electrodes that are crafted for outstanding performance in tough, corrosive environments. These low-carbon electrodes are specifically designed for welding molybdenum-bearing austenitic stainless steels, offering remarkable resistance to intergranular corrosion and pitting. Aditya Stainless is dedicated to maintaining consistent quality and adhering to international standards, providing dependable welding solutions for challenging industrial applications. With a strong focus on product integrity, timely delivery, and customer satisfaction, Aditya Stainless has earned a solid reputation in both the Indian and global welding markets, confidently supplying E317L-16 electrodes to critical industries.

AWS Class E317L-16 Electrodes are made up of high chromium (18–20%), nickel (12–14%), and molybdenum (3–4%) with a very low carbon content (maximum 0.04%). This unique blend significantly boosts corrosion resistance, particularly in environments with chlorides and other harsh chemicals. The weld metal boasts a tensile strength of around 580–700 MPa, a yield strength of about 350 MPa, and an elongation of roughly 30%. E317L-16 electrodes are known for their smooth arc operation, minimal spatter, and easy slag removal. The low carbon content ensures excellent resistance to intergranular corrosion, making them perfect for critical fabrication and maintenance tasks in demanding service conditions.

| Classification | AWS A5.4, E317L-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E317L-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 18.0-21.0 | 12.0-14.0 | 3.0-4.0 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer robust resistance to corrosion and are designed for welding 317L stainless steel. They typically come in sizes ranging from 2.5 mm to 4.0 mm in diameter. Their light coating ensures ease of handling and a smooth welding arc.

Featuring enhanced protection against corrosion, these electrodes are ideal for welding 317L stainless steel under demanding conditions. They are available in diameters of 3.2 mm to 5.0 mm, with a thicker coating for increased durability and stability during welding.

These electrodes provide superior corrosion resistance and are suited for welding stainless steel in environments requiring high protection. Available in sizes from 2.5 mm to 4.0 mm, they offer reliable performance with a shielded arc to prevent contamination and oxidation.

Aditya Stainless ensures the highest quality of AWS Class E317L-16 Electrodes through rigorous testing, including hardness, chemical analysis, PMI, tensile, micro and macro structural tests, pitting resistance, and IGC testing. We guarantee superior product performance with these comprehensive checks. Additionally, we provide all necessary documentation, including commercial invoices, packaging lists, and Certificate of Origin, legalized by the Chamber of Commerce or Embassy. Our Third-Party Inspection Certificate guarantees full customer satisfaction in pricing and delivery.

AWS Class E317L-16 Welding Electrodes find extensive use in industries where superior corrosion resistance is crucial, such as chemical processing, pharmaceuticals, pulp and paper, and food processing. These electrodes are particularly effective for welding stainless steels with similar compositions, especially those that face exposure to acids, chlorides, and high-moisture environments. Typical applications include storage tanks, heat exchangers, piping systems, and evaporators.

©2024 Aditya Stainless All Rights Reserved.