Home > Electrodes > AWS Class Er308/308h Saw and Flux

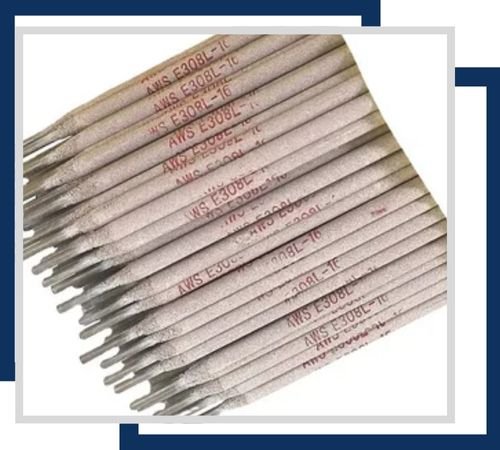

Aditya Stainless, located in Kolkata, India, stands out as a leading manufacturer and supplier of top-notch stainless steel welding consumables, such as AWS Class ER308/308H SAW Wire and Flux. These materials are specifically crafted for submerged arc welding of austenitic stainless steels like 304 and 304H, offering remarkable weldability, mechanical strength, and impressive resistance to oxidation and corrosion. The ER308/308H grade is particularly well-suited for high-temperature applications, with the higher carbon content in 308H providing enhanced creep resistance. When paired with high-quality flux, our products guarantee deep weld penetration, easy slag removal, and minimal spatter, ensuring reliable results in challenging industrial fabrication tasks.

ER308/308H SAW Wire generally consists of 18–21% chromium and 9–11% nickel, with carbon levels around 0.04–0.08% for 308 and 0.04–0.10% for 308H. The increased carbon in 308H boosts its strength at high temperatures and improves creep resistance. Its mechanical properties feature a tensile strength of at least 80,000 psi (550 MPa), yield strength of at least 55,000 psi (380 MPa), and an elongation of about 30%. When used with compatible neutral or basic fluxes, this system creates welds that not only look great but also have low porosity and strong corrosion resistance, especially in oxidizing environments and under high-temperature conditions.

| Classification | AWS A5.9, ER308/308H |

| Form | Welding Fluxes and Wires |

| Type Of Welding | Submerged Arc Welding |

| Thickness available | Upto 4 mm |

| AWS ER308/308H SAW & Flux Application & uses |

|

| C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| 0.04-0.08 | 1.0-2.5 | 0.30-0.65 | 19.5-22.0 | 9.0-11.0 | 0.03 | 0.03 | 0.50 | 0.75 |

| Tensile Strength | 86,500 psi |

|---|---|

| Yield Strength | 57,500 psi |

| Elongation (%) | 39% |

Contact us to get a quick quote for your requirement.

Alloy 308/308H SAW and Flux are used for submerged arc welding of stainless steel, providing strong, durable welds with excellent corrosion resistance, ideal for high-strength, high-temperature applications.

AWS A5.9 ER308/308H SAW and Flux Welding Wire is designed for submerged arc welding of stainless steel, offering superior weld quality, high strength, and excellent corrosion resistance in various industrial applications.

AWS Class ER308/308H Submerged Arc Welding Flux enhances the welding process by providing a clean, slag-free weld with minimal spatter, offering excellent corrosion resistance and strength for stainless steel applications.

Each AWS Class ER308/308H SAW and Flux Box is often custom packaged with the highest quality material for a high-end feel. No harm or contamination during transportation, which very much means we have the most efficient methods of moving it. We have a seamless delivery method to always deliver on time. We lay great stress on your satisfaction. The documentations include all the important things like certificates and product details. Are provided to our clients at the time of delivery assuring complete transparency and reliability in our services.

AWS ER308/308H SAW Wire and Flux are perfect for welding austenitic stainless steels such as 304, 304H, 308, and similar grades in situations that demand corrosion resistance and strength at elevated temperatures. These applications include pressure vessels, heat exchangers, boilers, piping systems, and structural components in the chemical, petrochemical, and power generation sectors. The higher carbon variant (308H) excels in high-temperature environments where creep resistance is crucial. The SAW process enables high deposition rates and deep penetration, making it ideal for welding thick sections.

©2024 Aditya Stainless All Rights Reserved.