Home > Electrodes > AWS Class ER308/308L SAW and FLUX

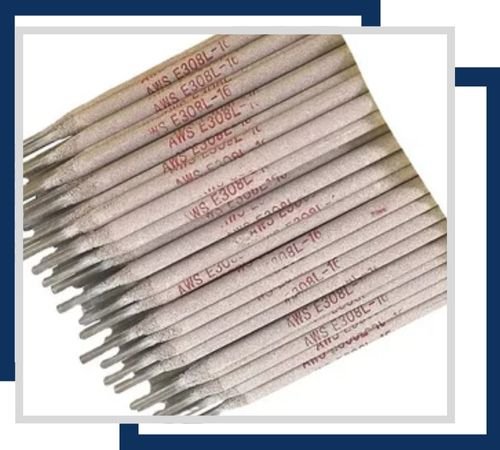

Aditya Stainless, a reputable manufacturer and supplier located in Kolkata, India, specializes in high-quality AWS Class ER308/308L Submerged Arc Welding (SAW) Wire and Flux. These products are specifically designed for welding austenitic stainless steels in tough industrial settings. This filler metal is perfect for joining 18Cr-8Ni stainless steels like 304 and 304L, especially when a low carbon content is necessary to avoid intergranular corrosion. When paired with the right flux, it ensures excellent slag removal, stable arcs, and a smooth bead finish. Commonly used in pressure vessels, structural components, and piping systems, ER308/308L SAW wire guarantees strong, corrosion-resistant welds with minimal contamination.

ER308/308L SAW wire is composed of 19.5–22% chromium, 9–11% nickel, and a maximum carbon content of 0.03% (for the “L” version). This blend provides outstanding corrosion resistance and weldability. When used alongside compatible SAW flux, the typical mechanical properties of the deposited weld metal include a tensile strength of at least 75,000 psi (520 MPa), yield strength of at least 55,000 psi (380 MPa), and an elongation of about 30%. The low carbon content helps reduce the risk of carbide precipitation, maintaining corrosion resistance even in high-temperature or corrosive environments. Welds remain ductile, robust, and stable under both mechanical and thermal stresses.

| Classification | AWS A5.9, ER308/308L |

| Form | Welding Fluxes and Wires |

| Type Of Welding | Submerged Arc Welding |

| Thickness available | Upto 4 mm |

| AWS ER308/308L SAW & Flux Application & uses |

|

| C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| 0.04-0.08 | 1.0-2.5 | 0.30-0.65 | 19.5-22.0 | 9.0-11.0 | 0.03 | 0.03 | 0.50 | 0.75 |

| Tensile Strength | 86,500 psi |

|---|---|

| Yield Strength | 57,500 psi |

| Elongation (%) | 39% |

Contact us to get a quick quote for your requirement.

Alloy ER308/308L SAW and Flux are used in submerged arc welding for stainless steel, providing high-quality, strong welds with excellent corrosion resistance and a clean, slag-free finish.

AWS A5.9 ER308/308L SAW and Flux Welding Wire is designed for submerged arc welding of stainless steel, offering high-strength welds, superior corrosion resistance, and a smooth, slag-free finish.

AWS Class ER308/308L Submerged Arc Welding Flux provides excellent arc stability and weld quality, producing clean, slag-free welds with high corrosion resistance and strength for stainless steel applications.

After the production of AWS Class ER308/308L SAW and Flux, our quality control team conducts thorough checks using both destructive and non-destructive testing methods to ensure the highest standards of performance and reliability. We use advanced techniques to test the products weldability and corrosion resistance. We make sure that it meets the stringent requirements of our clients. Once verified we package the SAW and Flux with the utmost care to avoid any damage during shipping. Timely delivery is our priority and we make sure that the products reach the customer without delay. All relevant documentation is provided to the clients at the time of delivery for complete transparency and assurance.

AWS ER308/308L SAW wire and flux are mainly utilized for submerged arc welding of 304 and 304L stainless steel in large fabrication projects. Their applications span pressure vessels, boilers, storage tanks, chemical processing equipment, food-grade piping, and other components where corrosion resistance and structural integrity are paramount. This wire excels in thick section welding and long production runs, delivering high deposition rates, excellent bead quality, and minimal spatter. The low carbon content is especially advantageous in applications where resistance to corrosion is crucial.

©2024 Aditya Stainless All Rights Reserved.