Home > Electrodes > AWS Class ER317L Mig & Tig Filler Welding Wire & Rod

Aditya Stainless, a well-respected manufacturer and supplier located in Kolkata, India, specializes in high-quality AWS Class ER317L MIG and TIG Filler Welding Wire and Rod. These products are specifically crafted for top-notch welding of molybdenum-bearing austenitic stainless steels. With a higher molybdenum content than ER316L, ER317L offers exceptional resistance to pitting, crevice corrosion, and chemical attacks, particularly in environments rich in chlorides and acids. Its low carbon content minimizes carbide precipitation during welding, ensuring outstanding intergranular corrosion resistance. This filler metal is perfect for critical applications in sectors like chemical processing, pharmaceuticals, marine, and pulp & paper, where long-lasting corrosion resistance is a must.

ER317L typically comprises 18–20% chromium, 12.5–14.5% nickel, 3–4% molybdenum, and ≤0.03% carbon. The extra molybdenum significantly boosts resistance to localized corrosion, especially in harsh chloride or sulfuric acid settings. Its mechanical properties include a tensile strength of at least 75,000 psi (520 MPa), yield strength of at least 50,000 psi (345 MPa), and an elongation of around 30%. The low carbon content helps preserve corrosion resistance post-welding. Additionally, this filler metal boasts excellent ductility and toughness, making it ideal for components that face cyclic thermal loads and corrosive environments in industrial settings.

| Classification | AWS A5.9, ER317L |

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Current | MIG-DCEP / TIG-DCEN |

| Diameters | .023”, .030”, .035”, .045”, 1/16”, 3/32”, 1/8” |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ER317L MIG & TIG Filler Metal Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.03 | 18.5-20.5 | 13.0-15.0 | 3.0-4.0 | 1.0-2.5 | 0.30-0.65 | 0.03 | 0.03 | 0.75 |

| Tensile Strength, kpsi: | 83* |

| Yield Strength, kpsi: | 60* |

| Elongation %: | 42* |

Contact us to get a quick quote for your requirement.

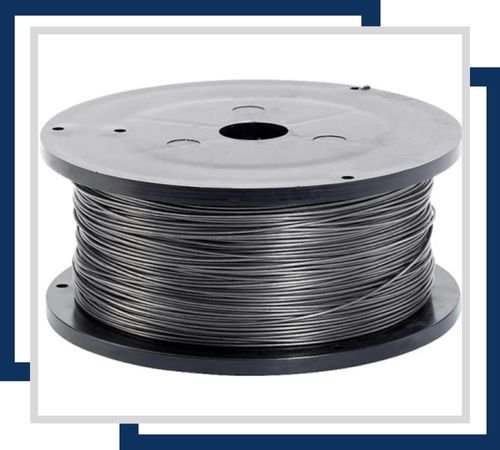

This MIG filler wire is available in sizes such as 0.030″, 0.035″, and 0.045″ diameter. It offers excellent corrosion resistance and is ideal for welding stainless steels with high molybdenum content. Its low carbon content helps minimize carbide precipitation.

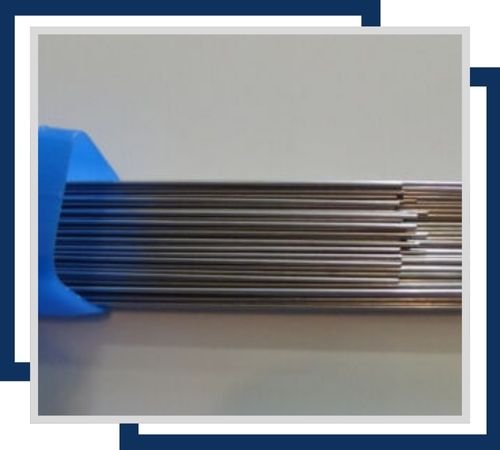

Available in diameters like 1/16″, 3/32″, and 1/8″, this TIG filler wire provides superior corrosion resistance. It is suitable for welding similar stainless steel alloys and maintains a low carbon content to prevent carbide formation.

Typically offered in sizes of 1/16″, 3/32″, and 1/8″ diameter, this filler rod is known for its excellent resistance to corrosion and high strength. It’s designed for use in TIG welding applications requiring enhanced resistance to pitting and crevice corrosion.

After manufacturing, our quality control team conducts both destructive and non-destructive tests using advanced tools to ensure the performance and reliability of the AWS Class ER317L MIG and TIG Filler Welding Wire and Rod. Once tested we pack the products securely to maintain their quality during transit and ensure timely delivery to customers. All relevant documents are provided to clients at the time of delivery for full transparency and assurance.

AWS ER317L MIG and TIG Filler Welding Wire and Rod are designed for welding base metals of similar composition, particularly 317 and 317L stainless steels, where enhanced corrosion resistance is crucial. These wires and rods find applications in equipment and piping within chemical plants, desalination systems, marine environments, pulp and paper mills, and food processing facilities. ER317L is particularly well-suited for use in acidic and chloride-laden environments. It can be utilized in both manual and automated welding processes, providing smooth and reliable results.

©2024 Aditya Stainless All Rights Reserved.