Home > Dairy Fittings > Dairy SMS Union

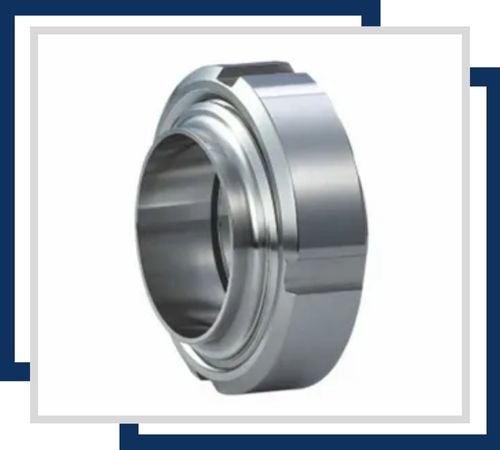

Aditya Stainless stands out as a top manufacturer and supplier of Dairy SMS Unions in Kolkata, India. We specialize in providing hygienic, high-quality pipe fittings tailored for the food, beverage, dairy, and pharmaceutical sectors. Our SMS (Swedish Manufacturing Standard) Unions are a go-to choice for sanitary processing lines, thanks to their easy assembly, excellent sealing capabilities, and cleanability. Crafted from premium stainless steel grades like 304 and 316L, our SMS Unions are built to last, offering durability, corrosion resistance, and hygienic performance. Each union features a male part, liner, nut, and gasket, ensuring a leak-proof and sterile connection that’s perfect for high-purity liquid transfer applications.

Dairy SMS Unions are primarily constructed from stainless steel 304 or 316L. SS 304 is composed of about 18% chromium and 8% nickel, while SS 316L boasts 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, which significantly boosts its resistance to chlorides and chemicals. These fittings exhibit a tensile strength of at least 515 MPa, yield strength of at least 205 MPa, and elongation of at least 40%. They are non-reactive, corrosion-resistant, and polished on the inside for sanitary applications. Designed with cleanliness in mind, SMS Unions facilitate smooth flow transitions and are perfect for frequent cleaning and sterilization in CIP (Clean-In-Place) systems.

Specification : Dn20-150 & 3/4″-6″,19MM-152.4MM

Standard : ISO, DIN11850,DIN11851, SMS,IDF

Parts of complete union : Liner,nut,male and gaskets

Shape of nut : Hexagonal shape,Round shape

Material : SS 304, SS 316L

Temperature : -20degree celsius~135degree celsius

Contact us to get a quick quote for your requirement.

We ensures that all products supplied to Dairy SMS Union meet the highest standards. Every piece of stainless steel undergoes rigorous testing, including mechanical, chemical and finish checks. The company offers comprehensive certifications, ensures compliance with industry regulations and emphasizes reliability and the durability of their products.

SS 304 SMS Union is a common choice for dairy applications due to its excellent corrosion resistance and durability. It provides a reliable and hygienic connection for dairy processing equipment, ensuring long-lasting performance and ease of maintenance.

Stainless Steel Dairy SMS Union is designed for sanitary applications in the dairy industry. Its stainless steel construction ensures resistance to corrosion and contamination, maintaining the purity of the dairy products while providing a secure, leak-proof connection.

Stainless Steel 316 Dairy Union offers superior resistance to corrosion and high temperatures, making it ideal for demanding dairy applications. Its robust design ensures reliability in harsh environments, maintaining hygiene and durability.

Stainless Steel SMS Union Ring Joint features a ring joint design that ensures a tight seal, preventing leaks and contamination in dairy systems. The stainless steel material provides excellent resistance to corrosion and ease of cleaning, enhancing the overall safety and performance of dairy equipment.

Stainless Steel SMS Union Dairy Fittings are designed for dairy applications, offering a seamless connection that meets sanitary standards. These fittings ensure durability, ease of assembly, and maintenance while providing resistance to corrosion and ensuring product integrity.

Stainless Steel 316L SMS Union is crafted from low-carbon 316 stainless steel, offering enhanced corrosion resistance and strength. It is particularly suited for high-purity dairy applications, where maintaining cleanliness and durability is crucial.

Dairy SMS Unions play a crucial role in hygienic piping systems across the dairy, food processing, beverage, cosmetics, brewery, and pharmaceutical industries. They offer a quick-release, sanitary connection between pipe segments, ensuring leak-proof operation and easy disassembly for cleaning and maintenance. You’ll find SMS Unions widely used in milk processing plants, breweries, water treatment systems, syrup lines, and CIP systems, where hygiene and contamination control are paramount. Their sturdy design and corrosion resistance make them ideal for transporting liquids and semi-liquids under low to moderate pressure, ensuring operational efficiency.

©2024 Aditya Stainless All Rights Reserved.