Aditya Stainless stands out as a reliable manufacturer and supplier based in Kolkata, India, specializing in top-notch Stainless Steel 314 Bars designed for tough, high-temperature, and corrosive industrial settings. Crafted from high-quality raw materials and cutting-edge techniques, these bars promise durability, strength, and resistance to oxidation. They perform exceptionally well even when exposed to temperatures soaring up to 1150°C, making them perfect for applications in thermal processing, heat exchangers, and furnace components. Aditya Stainless offers precision-engineered 314 stainless bars in a variety of shapes and sizes, all while adhering to international standards to cater to industries like petrochemical, aerospace, automotive, and metallurgy.

Stainless Steel 314 Bars are made up of 24–26% chromium, 19–22% nickel, a maximum of 0.25% carbon, and up to 2.5% silicon, which gives them remarkable resistance to oxidation and carburization. These bars boast a tensile strength ranging from 550 to 650 MPa, a yield strength of about 210 MPa, and an elongation of 30%, ensuring they maintain good formability and strength even at high temperatures. They retain their mechanical properties even above 1000°C and offer excellent creep resistance, making them ideal for high-stress and high-heat industrial applications.

Specification : ASTM A276, A479 / ASME SA276, SA479

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Round Bars : Outside Diameter in the range of 4mm to 500mm

Bright Bars : Outside Diameter in the range of 4mm to 100mm

Hex Bars : 18mm – 57mm (11/16″ to 2-3/4″)

Square Bars : 18mm – 47mm (11/16″ to 1-3/4″)

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Length : 1 to 6 Meters, Custom Cut Lengths

Form : Round, Square, Hex (A/F), Rectangle Etc.

| Element | Content (%) |

|---|---|

| Iron, fe | Balance |

| Chromium, Cr | 19-26 |

| Nickel, Ni | 19-22 |

| Manganese, Mn | 2 |

| Silicon, Si | 1.5-3 |

| Carbon, C | 0.25 |

| Sulfur, S | 0.03 |

| Phosphorous, P | 0.045 |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 689 MPa | 99900 psi |

| Yield strength | 345 MPa | 50000 psi |

| Modulus of elasticity | 200 GPa | 29000 ksi |

| Elongation at break (in 50 mm) | 40% | 40% |

| Hardness, Rockwell B | 85 | 85 |

Contact us to get a quick quote for your requirement.

We ensures that it provides the most excellent quality on Stainless Steel 314 Bars in terms of being tested and certification. Each and every bar passed through the high-quality mechanical, chemical analysis; tensile strength, hardness strength, corrosion testing, and with reports like a Mill Test Certificate, which verifies the industry specification and customer satisfaction.

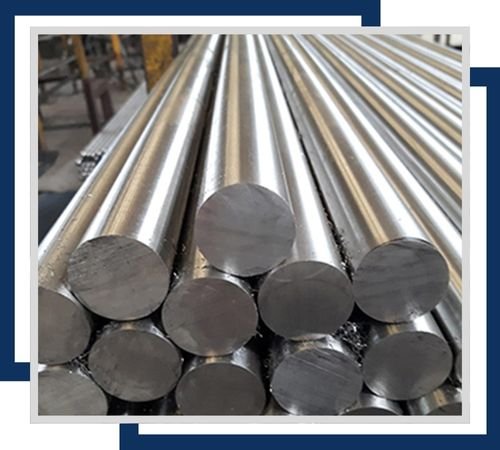

Corrosion-resistant and designed for high-temperature applications, Stainless Steel 314 Round Bars are available in diameters from 0.5″ to 12″. Ideal for use in industrial equipment and heat exchangers.

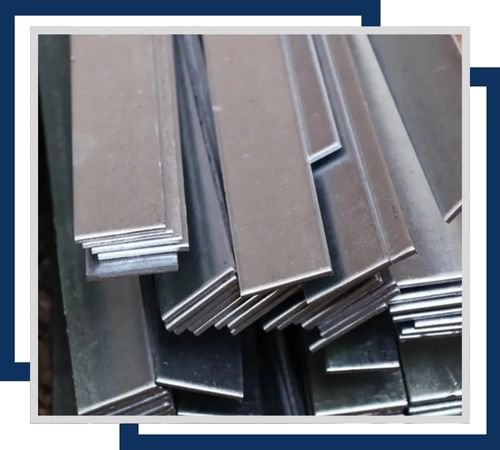

Stainless Steel 314 Flat Bars offer excellent resistance to high temperatures, available in thicknesses from 0.25″ to 6″ and widths up to 12″. Perfect for structural components and industrial uses.

Featuring superior heat resistance, Stainless Steel 314 Square Bars come in sizes from 0.5″ to 6″ on each side. They are suitable for applications requiring high strength and thermal stability.

Stainless Steel 314 Rectangular Bars provide excellent high-temperature resistance, available in sizes from 0.5″ x 1″ to 6″ x 12″. Ideal for heavy-duty applications and components exposed to extreme conditions.

Offering exceptional heat resistance, Stainless Steel 314 Hexagonal Bars are available in sizes from 0.5″ to 4″ across flats. Suitable for aerospace and chemical processing applications requiring durable performance.

Corrosion-resistant Stainless Steel 314 T-Bars come in dimensions from 0.5″ x 0.5″ to 6″ x 6″. They are ideal for structural applications and machinery needing high-temperature strength and durability.

SS 314 Bars find extensive use in heat treatment equipment, furnace construction, kilns, and radiant heating systems, thanks to their outstanding high-temperature stability and oxidation resistance. Industries like power generation, chemical processing, and metal refining depend on these bars for components that endure intense thermal cycling. Typical applications include support structures, fixtures, tubesheets, and machined parts in high-temperature areas. Moreover, they are also utilized in the automotive and aerospace industries for exhaust systems and other components that need to withstand prolonged exposure to elevated heat.

©2024 Aditya Stainless All Rights Reserved.