Home > Stainless Steel 316/316L Channels

Aditya Stainless is a reputable manufacturer and supplier of Stainless Steel 316/316L Forged Fittings, proudly based in Kolkata, India. We provide top-notch forged fittings that are celebrated for their exceptional corrosion resistance, durability, and ability to handle high pressure. SS 316 is enriched with molybdenum, which boosts its resistance to pitting and crevice corrosion, while SS 316L, the low-carbon variant, offers enhanced weldability and resistance to intergranular corrosion. Our range of forged fittings, including elbows, tees, couplings, unions, and plugs, is extensively utilized in high-pressure settings. With precise dimensions and adherence to international standards, Aditya Stainless ensures reliable forged fittings for critical industrial systems and fluid transfer lines.

Stainless Steel 316/316L Channels are made up of 16–18% Chromium, 10–14% Nickel, and 2–3% Molybdenum, with SS 316L having a maximum carbon content of 0.03%. These components offer remarkable resistance to pitting, crevice corrosion, and damage from the atmosphere. The mechanical properties include a tensile strength of about 515 MPa, yield strength of 205 MPa, and an elongation of 40%, making them ideal for handling structural loads. The low carbon content in SS 316L enhances its weldability and minimizes the risk of intergranular corrosion, making it a great choice for welded structures and critical environments.

| Standard | ASTM A276, ASTM A479 / ASME SA276, ASME SA479 |

| Condition | HRAP |

| Size Range | Base: 80 to 150 mm Side: 40 to 75 mm |

| Thickness | 5 to 6 mm (depending on size) |

| Grades | 304, 316 |

| Processing | Bar cutting |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 1.0 max | 16.00 – 18.00 | 16.00 – 18.00 | 10.00 – 14.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

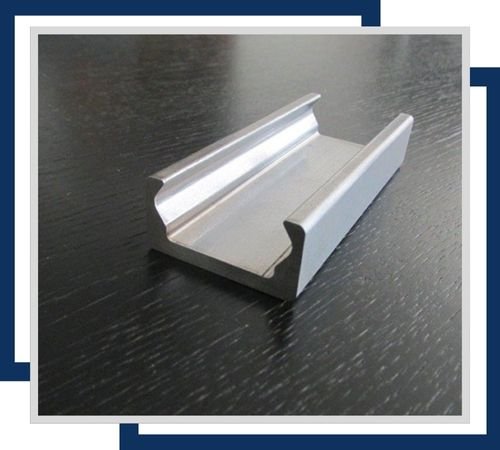

Stainless Steel 316/316L channels are structural elements made from corrosion-resistant stainless steel. They provide high strength and durability, ideal for marine, chemical, and high-temperature applications.

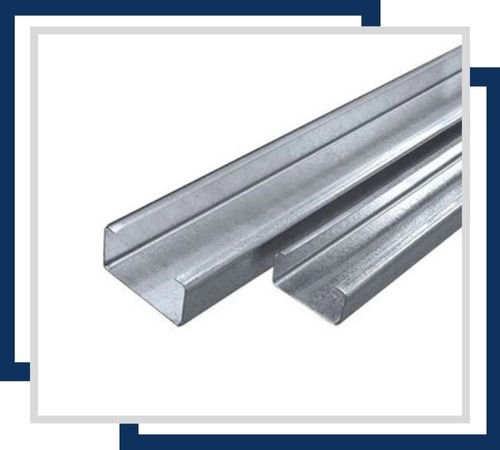

SS 316/316L C channels are stainless steel sections shaped like a “C,” offering high strength and superior corrosion resistance. They are used for support and framing in demanding environments.

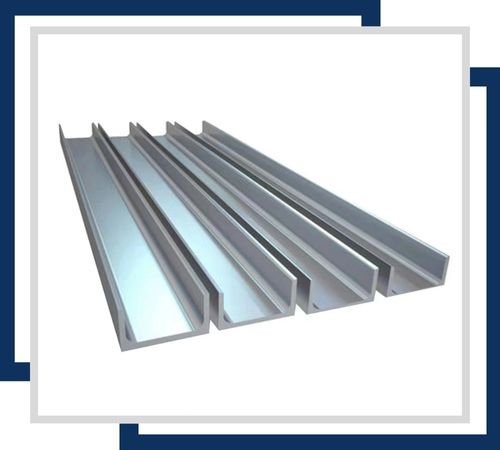

Stainless Steel 316/316L U channels are structural components with a “U” shape, known for excellent strength and corrosion resistance. They are used in marine, chemical, and high-temperature environments for support and reinforcement.

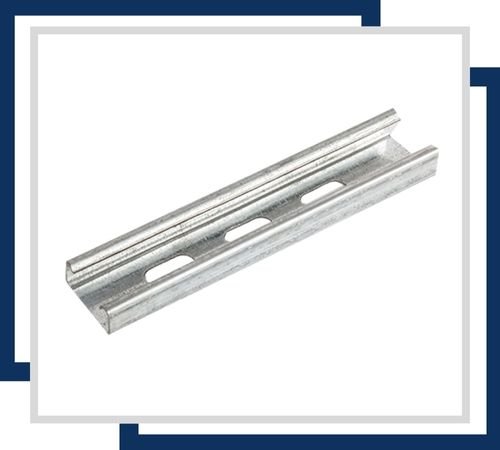

SS 316/316L strut C channels are stainless steel sections with a “C” shape, designed for robust support and framing. They offer high strength, durability, and excellent corrosion resistance for industrial applications.

SS 316/316L cold-rolled Unistrut channels are stainless steel channels produced through cold rolling. They offer high strength, excellent corrosion resistance, and are used for versatile support and framing in demanding environments.

SS 316/316L double C type channels are stainless steel sections with two “C” shapes back-to-back. They provide enhanced strength and stability, suitable for heavy-duty support and structural applications in harsh environments.

Each Stainless Steel 316/316L Channel is carefully packed with the use of best materials for its prevention from undergoing damages upon corrosion whether in processing or during shipping to its destination. Packing the materials as such, we always see to it that our orders reach our customers in the best possible and timely way due to available transport systems and modes. Requisite accompanying documentation all highest will be handed over to customers as soon as delivery is accomplished to make the deal seem smooth and transparent.

Stainless Steel 316/316L Channels find extensive use in structural applications that demand high strength and corrosion resistance. They are perfect for marine structures, chemical plants, oil and gas platforms, pharmaceutical frameworks, and food processing equipment. These channels provide solid support in bracing systems, architectural frameworks, fabrication projects, and equipment chassis. Thanks to their molybdenum content, they are particularly valuable in environments that are exposed to chlorides and acidic media, such as coastal areas and chemical zones. Their ease of weldability and long-lasting durability make them a go-to choice for various applications.

©2024 Aditya Stainless All Rights Reserved.