Aditya Stainless has made a name for itself as a leading manufacturer and supplier of Stainless Steel 316Ti Coils in Kolkata, India. We pride ourselves on delivering top-notch coils that are specifically designed to thrive in high-temperature and highly corrosive settings. SS 316Ti is a titanium-stabilized austenitic stainless steel, which significantly boosts its resistance to intergranular corrosion, especially in welded structures and during thermal cycling. Our coils are crafted in line with ASTM A240 and other international standards, making them perfect for critical applications in chemical plants, marine environments, heat exchangers, and food processing units. Plus, we offer a range of thicknesses, finishes, and custom-cut sizes to cater to various industry needs.

Stainless Steel 316Ti Coils are made up of 16–18% chromium, 10–14% nickel, 2–3% molybdenum, and titanium (typically five times the carbon content) to keep the material stable against carbide precipitation. This unique composition gives them outstanding resistance to intergranular corrosion, even after long exposure to high temperatures. These coils boast a tensile strength of 515–730 MPa, a yield strength of about 205 MPa, and an elongation of 30–40%. The molybdenum content enhances their resistance to pitting and crevice corrosion, especially in environments rich in chlorides, making these coils a dependable choice for tough industrial conditions.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Coil Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm etc. |

| Coil Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Galvanized etc. |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 316Ti | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24 – 26 | 0.75 max | 19 – 21 | 53.095 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Contact us to get a quick quote for your requirement.

SS 316Ti slitting coils are versatile strips that have many applications in industrial sectors. Due to superior corrosion resistance, the strips can offer durability and strength for manufacturing different components, and marine and chemical processing applications.

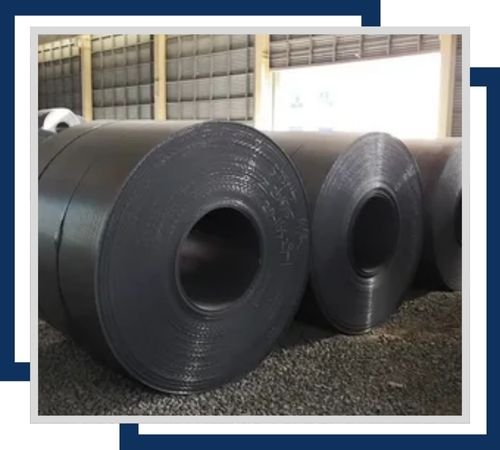

SS 316Ti hot rolled coils are hot rolled coils of excellent corrosion resistance. They have application in structural, marine, chemical, and other industrial applications to provide durability as well as versatility in harsh environmental conditions.

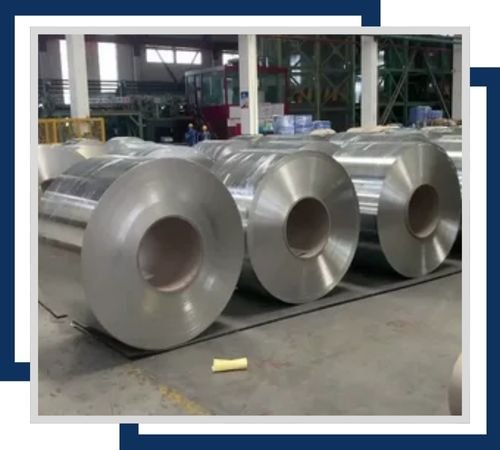

SS 316Ti is supplied as Cold Rolled Coils with superior surface finish and dimensional accuracy. For precision engineering applications, SS 316Ti offers excellent corrosion resistance and strength for automotive, aerospace, and architectural uses.

Stainless Steel 316Ti HR coils slitting features high corrosion strength and resistance to corrosion. They come in handy while precision cutting for manufacturing purposes like in marine chemical, and in industries that work with high-performing and solid material.

These Stainless Steel 316Ti are the slitting coils that provide wonderful corrosion resistance. It is usually ideal for good precision cutting hence applied in use in marine applications, chemical fields, and high-performance industrial functions.

AISI 316Ti slitting coils have superior corrosion resistance and strength. They are best suited for precision cutting and industrial applications, such as marine, chemical processing, and high-performance environments, for reliable durability.

Aditya Stainless commits to making purchases hassle-free for our customers with complete documentation on our high-quality Stainless Steel 316Ti Coils. This comprises essential commercial invoices, packing lists, fumigation certificates, heat treatment charts, quality assurance plans, and NABL-approved lab test reports, which are authentic and superior in quality. Also, Stainless Steel 316Ti Coils are accompanied with Test Certificate as EN10204 3.1B/PMI Destruction Certificate/Third-Party Survey with 100% Radiography Test Report along with third party inspection. With this, a dedication to fulfilling high standards would result in satisfied customers.

Stainless Steel 316Ti Coils find their place in various industries that demand materials resistant to corrosion and heat, including chemical processing, power generation, marine engineering, oil & gas, and pharmaceutical manufacturing. They are perfect for creating tanks, vessels, exhaust systems, pressure equipment, and food-grade processing systems. Their ability to withstand thermal fatigue, oxidation, and post-weld corrosion makes them ideal for welded structures, heat exchangers, and flue gas systems. Additionally, 316Ti coils are frequently used in architectural applications, showcasing their versatility and reliability.

©2024 Aditya Stainless All Rights Reserved.