Aditya Stainless stands out as a leading manufacturer and supplier of Stainless Steel 321H Tubing, proudly based in Kolkata, India. These tubes are specifically crafted for high-temperature and high-pressure applications, utilizing a titanium-stabilized austenitic stainless steel alloy that features a higher carbon content for added strength. Our SS 321H tubing is known for its exceptional resistance to oxidation, intergranular corrosion, and creep deformation, even in elevated temperature settings. Offered in both seamless and welded forms, these tubes comply with international standards like ASTM A213, A269, and A312. They find their place in various sectors, including petrochemical, thermal, and power industries, and come in a range of sizes, wall thicknesses, and finishes.

Stainless Steel 321H Tubing is made up of chromium (17–19%), nickel (9–12%), and is stabilized with titanium, featuring an increased carbon content (up to 0.10%) to enhance its strength at high temperatures. Typically, these tubes deliver a tensile strength of 515–620 MPa, a yield strength of 205 MPa, and an elongation of about 35%. The alloy is renowned for its excellent oxidation resistance, creep resistance, and mechanical stability when exposed to high temperatures. The titanium stabilization effectively prevents sensitization, making these tubes particularly suitable for welded applications that endure prolonged heat exposure.

Standard ASTM A/ASME SA213/A249/A269/A312/A358 CL. I to V ASTM A789/A790

Dimensions ASTM, ASME and API

Range 1/2″ NB TO 24″ NB IN SCH 5, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160 & XXS as Per NACE MR 01 75

Thickness 0.3mm – 50 mm

Outer Diameter 6.00 mm OD up to 914.4 mm OD

Schedule SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS

Type Seamless / ERW / Welded/ Fabricated

Form Round, Square, Rectangular, Hydraulic, etc.

Length Single Random, Double Random & Cut Length

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

| Element | Grade 904L |

|---|---|

| Density | 8 |

| Melting Range | 1300 -1390 ℃ |

| Tensile Stress | 490 |

| Yield Stress (0.2%Offset) | 220 |

| Elongation | 35% minimum |

| Hardness (Brinell) | – |

Contact us to get a quick quote for your requirement.

We ensures the highest standards for its stainless steel 321H tubing through rigorous testing and certification processes. Each tube undergoes a thorough evaluation, including hydrostability, chemical testing and mechanical testing. Certified to international standards such as ASTM and ASME, these containers provide reliability, durability and high performance in demanding industrial applications.

This tubing is available in sizes ranging from 1/8″ to 24″ in outer diameter. It offers excellent corrosion resistance, especially against intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 427-816°C. Ideal for high-temperature applications requiring a continuous, strong, and uniform surface.

Available in dimensions from 1/8″ to 36″ in outer diameter, this tubing is known for its high resistance to stress and pitting corrosion. It’s frequently used in chemical processing and other high-temperature applications due to its robust performance under harsh conditions. The welding process ensures a strong, durable, and leak-proof seam

These tubes come in sizes from 1/4″ to 1″ in outer diameter, designed for excellent thermal conductivity and corrosion resistance. Ideal for high-temperature and high-pressure environments, they are used in industries such as petrochemical and power generation. Their composition resists scaling and oxidation even at elevated temperatures.

Offered in sizes from 1/8″ to 2″ in outer diameter, this tubing provides superior resistance to corrosion and high temperatures. It is used in precision instrumentation and control systems, ensuring reliable performance and accurate measurements. The tubing’s stability at high temperatures ensures minimal expansion and contraction.

These tubes, ranging from 1/2″ to 5″ in outer diameter, are designed to withstand high-pressure and high-temperature environments typical in boiler systems. They offer excellent corrosion resistance, especially against steam and hot gases. Their durability ensures long service life and reliability in energy and industrial applications.

Available in sizes from 1/4″ to 1″ in outer diameter, U-tubes are essential for heat exchanger applications requiring a compact and efficient design. They provide excellent corrosion resistance and thermal stability, making them suitable for use in petrochemical, oil refining, and power generation industries. The U-shape allows for efficient heat transfer in limited spaces.

These tubes come in sizes ranging from 1/4″ to 1″ in outer diameter and are designed for use in condenser applications where efficient heat transfer and resistance to corrosion are critical. They are commonly used in power plants, HVAC systems, and refrigeration. The tubes ensure minimal fouling and scaling over prolonged use.

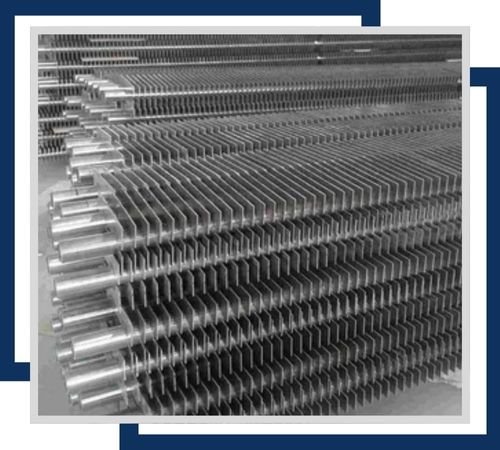

Fin tubes are available in sizes from 1/2″ to 2″ in outer diameter, designed to enhance heat transfer efficiency in various industrial applications. The addition of fins increases the surface area, improving thermal performance. These tubes offer excellent resistance to high-temperature oxidation and corrosion, making them ideal for heat exchangers and boilers.

Stainless Steel 321H Tubing is extensively utilized in scenarios that demand both high-temperature strength and corrosion resistance. It’s perfect for heat exchangers, boiler tubes, superheaters, and thermal oxidizers. In the petrochemical and power generation sectors, it serves as high-temperature piping and exhaust systems. You’ll also find this tubing in aerospace components, refinery equipment, and furnace operations, where thermal stability and scaling resistance are essential. Its ability to resist intergranular corrosion post-welding makes it a preferred choice for pressure vessels, chemical reactors, and welded assemblies that are exposed to challenging conditions.

©2024 Aditya Stainless All Rights Reserved.