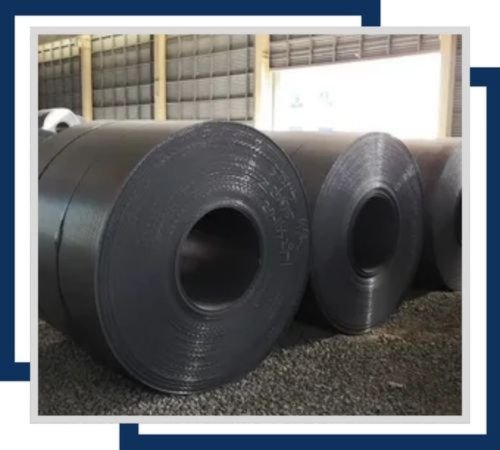

Aditya Stainless stands out as a top manufacturer and supplier of Stainless Steel Slitting Coils, proudly based in Kolkata, India. We specialize in precision-engineered coil products designed to cater to the varied demands of today’s industries. Our Stainless Steel Slitting Coils are crafted by slicing wide stainless steel coils into narrower strips, guaranteeing tight dimensional tolerances and smooth edges. Available in grades like 304, 316, 430, 201, and 409, our products meet international standards for durability and performance. With cutting-edge processing facilities, we provide slitting coils that are perfect for automotive, electronics, HVAC, kitchenware, and construction applications.

Stainless Steel Slitting Coils mainly consist of chromium (16–20%) and nickel (8–14%), with possible additions of elements like manganese, molybdenum, or titanium, depending on the specific grade. These materials offer outstanding corrosion resistance, formability, and mechanical strength. In terms of mechanics, the coils boast a tensile strength ranging from 480–750 MPa, a yield strength of about 170–450 MPa, and an elongation of 30–45%. This makes them perfect for processes like forming, welding, and stamping. The slitting process maintains the material’s integrity, ensuring reliable performance across various fabrication needs.

Standard : ASTM A240, ASME SA240

Thickness : 0.2 mm – 16 mm

Width : 12 mm – 2000 mm

Length : In coil form

Finishes : No.1 (HR), 2B, 2D, BA, NO.1, NO.4, NO.8

Item : Stainless Steel Slitting Coils (Hot rolled, cold rolled), polish, finish, Bright Annealed

| Grade | Cr | Mn | Si | Ni | C | P | S | Fe |

| SS 410 | 11.50 – 13.50 | 0.0 – 1.50 | 0.0 – 1.00 | 0.0 – 0.75 | 0.08 – 0.15 | 0.0 – 0.04 | 0.0 – 0.02 | Balance |

| Tensile Strength Ksi (Mpa) | 0.2% Offset Yield Strength Ksi (Mpa) | Elongation, % in 2″ (51 mm) | Hardening Response HRC | HRB |

| 65 (450) – 74 (510) | 30 (205) – 42 (290) | 20 – 34 | 38-45 | 82-96 |

Contact us to get a quick quote for your requirement.

Stainless steel slitted coils are precision-cut strips of stainless steel used in manufacturing. They offer high corrosion resistance, durability, and are commonly used in automotive, construction, and appliance industries.

Cold rolled slitted coils are steel strips processed at room temperature, offering improved surface finish, tight tolerances, and increased strength, widely used in automotive, electronics, and appliance manufacturing.

No.1 finished slitted coils are stainless steel strips with a rough, dull finish achieved through hot rolling and annealing, typically used in industrial applications where surface smoothness is not critical.

2B finished slitted coils are stainless steel strips with a smooth, reflective surface achieved through cold rolling, annealing, and descaling, ideal for applications requiring aesthetic appeal and corrosion resistance.

At Aditya Stainless, the quality of materials forms the mainstay for ultimate customer satisfaction; thus, all our products such as stainless steel slitting coils undergo thorough quality testing. These quality tests include hardness tests, chemical analysis via spectro analysis, positive material identification (PMI) tests, flattening tests, examination micro and macro, pitting resistance tests, flaring tests, and finally Intergranular Corrosion (IGC) tests.

Stainless Steel Slitting Coils find extensive use in industries that require precise, narrow-width stainless steel strips. They play a crucial role in the automotive sector for exhaust components, trims, and brackets; in HVAC systems for ducting; and in appliances for panels and kitchen equipment. Additionally, they are utilized in the electronics industry for shielding and enclosures, as well as in construction for roofing, cladding, and flashing. Thanks to their excellent corrosion resistance, formability, and appealing finish, these coils are ideal for consumer goods, metal furniture, and industrial machinery.

©2024 Aditya Stainless All Rights Reserved.