Aditya Stainless stands out as a top manufacturer and supplier of Stainless Steel SMO 254 Bars in Kolkata, India. These premium-grade bars are specifically crafted to withstand extreme corrosion and high-strength applications. SMO 254 (UNS S31254) is a super austenitic stainless steel designed for chloride-rich environments, providing excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. Industries such as marine, offshore, chemical processing, pulp & paper, and desalination plants rely on these bars. Available in a variety of sizes, shapes, and finishes, SMO 254 bars are perfect for structural components, shafts, and high-performance fittings.

SMO 254 Bars are made up of about 20% chromium, 18% nickel, and 6% molybdenum, along with nitrogen and copper, which gives them outstanding chloride corrosion resistance and mechanical strength. These bars boast a tensile strength of at least 650 MPa, a yield strength of at least 300 MPa, and an elongation of around 35%, all while maintaining excellent impact toughness even in low temperatures. With a Pitting Resistance Equivalent Number (PREN) greater than 42, SMO 254 is well-suited for aggressive environments. The alloy also offers good weldability, formability, and fabrication characteristics, making it a dependable choice for both structural and pressure-based applications.

| Standards | EN, DIN, JIS, ASTM, BS, ASME, AISI |

|---|---|

| Size | 1/2″ to 100″ |

| Length | 100 mm to 6000 mm |

| Specifications | ASTM A276, A279, A479 |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Finish | Bright, Polish, Black |

| SMO 254 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Contact us to get a quick quote for your requirement.

We thoroughly tests and certifies its Stainless Steel SMO 254 Bars with the highest quality standards. Every product undergoes rigorous checks including chemical composition analysis, mechanical testing, and corrosion tests. Under relevant industry standards, these certified products could assure reliability and performance and ensure global specifications are met.

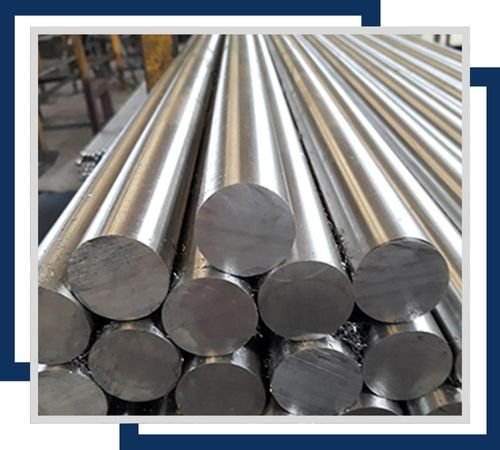

Stainless Steel SMO 254 Round Bars offer exceptional resistance to corrosion and high strength, ideal for marine and chemical processing applications. Their high molybdenum content ensures durability and performance in aggressive environments.

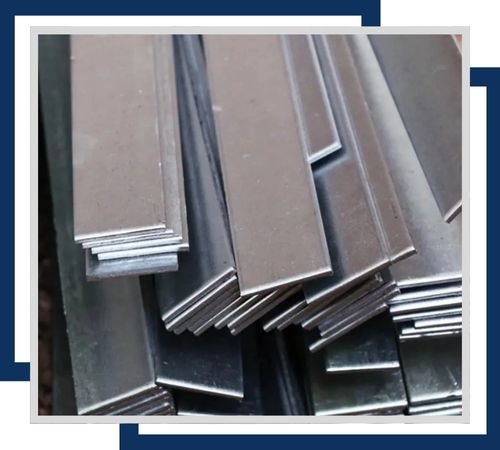

Stainless Steel SMO 254 Flat Bars provide superior resistance to corrosion and pitting, making them suitable for use in harsh marine and chemical environments. They are commonly used in structural components and equipment exposed to severe conditions.

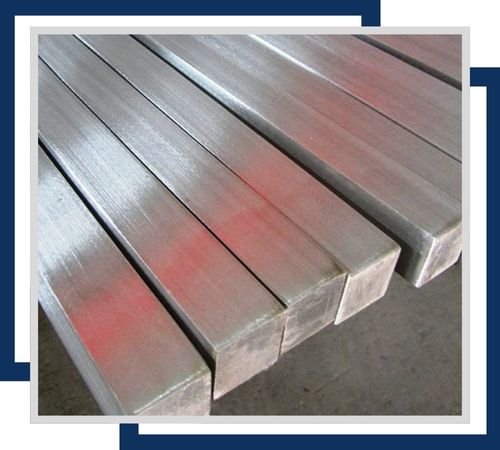

Stainless Steel SMO 254 Square Bars are designed for applications requiring high corrosion resistance and strength. They are ideal for use in chemical processing, marine environments, and offshore platforms, offering excellent durability and performance.

Stainless Steel SMO 254 Rectangular Bars are used in environments where resistance to corrosion and high strength are crucial. They are employed in structural supports, chemical processing equipment, and marine applications, ensuring long-lasting performance.

Stainless Steel SMO 254 Hexagonal Bars offer enhanced resistance to corrosion and oxidation, making them ideal for use in high-salinity and chemical environments. They are commonly used in marine applications and industrial components requiring superior durability.

Stainless Steel SMO 254 T-Bars provide exceptional strength and resistance to corrosive environments. They are suitable for structural applications, chemical processing equipment, and marine environments, ensuring reliability and longevity under extreme conditions.

Stainless Steel SMO 254 Bars are perfect for high-chloride and high-salinity environments where regular stainless steels fall short. They are commonly used in heat exchangers, pressure vessels, marine shafts, pumps, valves, piping systems, and chemical storage tanks. These bars are particularly effective in desalination plants, offshore oil platforms, flue-gas cleaning systems, and pulp bleaching equipment. Their remarkable ability to resist localized corrosion, even under intense chemical and mechanical stress, guarantees a long service life with minimal maintenance. SMO 254 bars are widely trusted for their combination of durability and performance.

©2024 Aditya Stainless All Rights Reserved.